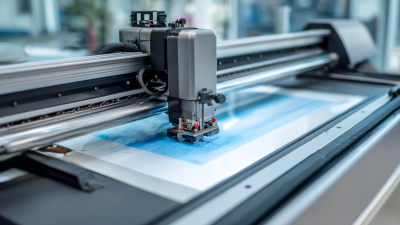

In the fast-evolving landscape of the automotive and manufacturing industries, the efficiency and precision of your Ppf Cutting Machine can significantly impact overall productivity and product quality. As the demand for high-performance paint protection films (PPF) continues to rise, it is crucial for businesses to leverage optimal cutting machine strategies. In this guide, we will explore essential tips to enhance the effectiveness of your Ppf Cutting Machine, ensuring that it operates at peak performance while maintaining the accuracy required for intricate designs.

Understanding the various factors that contribute to machine efficiency and precision can not only streamline your production processes but also reduce waste and operational costs. From maintenance routines to selecting the right cutting blades and software, every detail plays a pivotal role in maximizing the capabilities of your Ppf Cutting Machine. Join us as we delve into the top strategies to transform your cutting operations in 2025 and beyond, setting you on a path toward industry leadership and innovation.

Maximizing material usage is crucial for enhancing the efficiency of your PPF (Paint Protection Film) cutting machine. By strategically allocating resources and minimizing waste, businesses can significantly boost their productivity and profitability. According to industry reports, efficient material utilization can lead to potential savings of up to 30% in raw material costs. This not only reduces expenses but also minimizes environmental impact, aligning with modern sustainable practices.

To achieve optimal efficiency in PPF cutting, consider implementing software solutions that analyze cutting patterns and material layouts. Utilizing advanced algorithms, these systems maximize the use of available film, ensuring minimal wastage. Furthermore, by understanding the principles of economic efficiency—where the goal is to allocate resources in a manner that maximizes value—cutting machine operators can adopt techniques that optimize both the precision of cuts and the utilization of materials. The introduction of high-efficiency tools and techniques can elevate the overall performance of cutting operations, ensuring a more profitable and sustainable approach to PPF application.

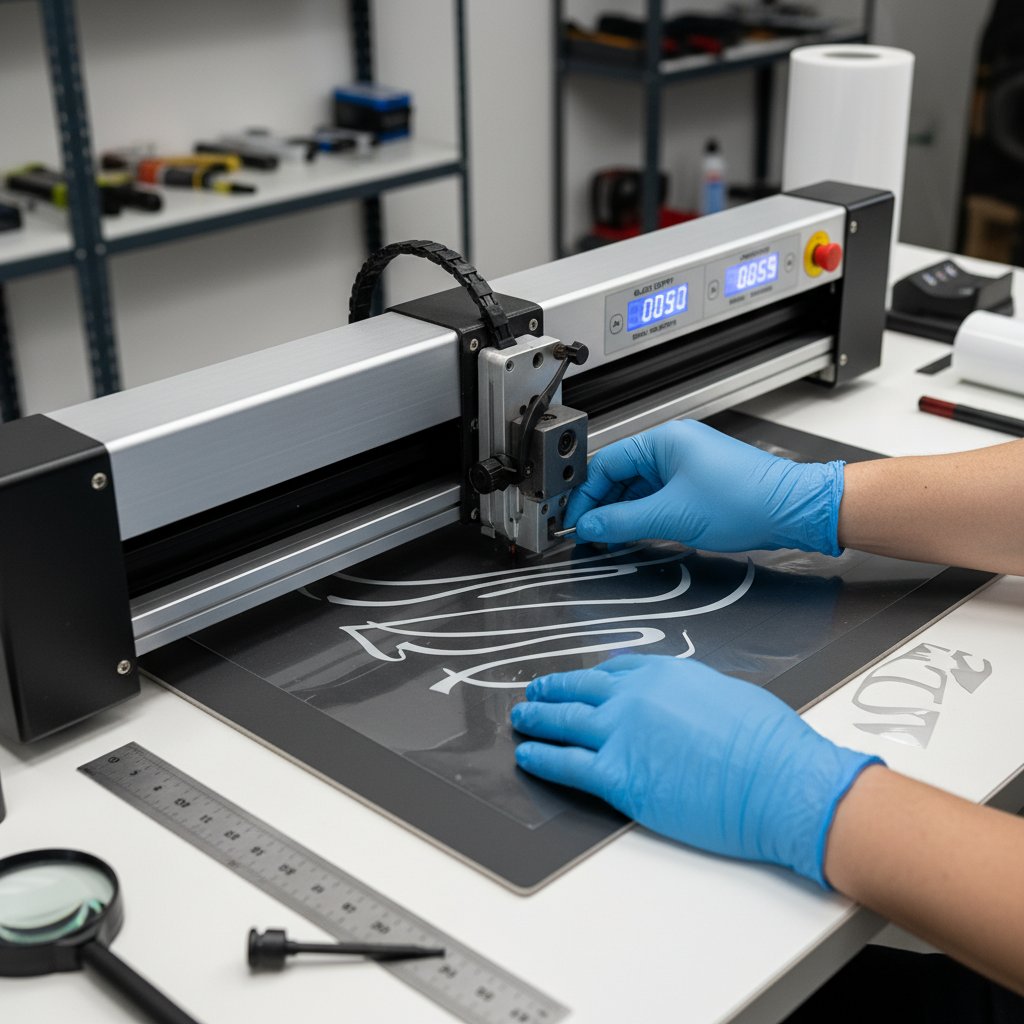

Calibrating your PPF cutter is an essential step toward achieving enhanced precision in your projects. Proper calibration ensures that the cutting machine operates at peak performance, which directly impacts the quality of the finished product. Regularly checking and adjusting the blade depth, speed, and pressure settings can make a significant difference. Start with a test cut to assess the accuracy and make necessary adjustments before proceeding with larger tasks.

To optimize efficiency, consider implementing a routine maintenance schedule. Regular cleaning of the cutting bed and blades will prevent debris buildup, which can lead to inaccurate cuts. Additionally, recalibrating the machine periodically, especially after heavy use or replacing blades, helps maintain consistent performance. Always keep the user manual handy for reference on specific calibration procedures tailored to your machine model.

Another tip is to invest in high-quality films and materials. The compatibility between the cutter and the PPF is crucial; using subpar materials may cause uneven cuts and compromise precision. By selecting premium products, you not only enhance the overall cutting process but also ensure the longevity and reliability of your PPF cutting machine.

Regular maintenance is crucial for sustaining the performance of your PPF cutting machine. Consistent checks and servicing can prevent costly breakdowns and ensure that the machine operates at peak efficiency. Begin with routine inspections, focusing on the blade condition and the cutting path. Dull or damaged blades not only compromise precision but can also lead to material waste, negatively impacting your overall productivity. Replace blades as needed and ensure that all components are free from debris and wear.

In addition to blade maintenance, lubrication is a key aspect that should not be overlooked. Regularly applying the appropriate lubricants to moving parts reduces friction and wear, extending the lifespan of the machine. Furthermore, calibrating the machine to meet specific material thickness and type regularly will enhance cutting accuracy. Establishing a maintenance schedule, adhering to the manufacturer’s guidelines, and keeping detailed records of all maintenance activities will help track performance and identify any recurring issues. By prioritizing these practices, you can significantly optimize your PPF cutting machine's efficiency and precision, ensuring consistent output quality.

| Maintenance Practice | Frequency | Expected Impact on Efficiency | Precision Improvement |

|---|---|---|---|

| Blade Replacement | Every 500 cuts | Increases cutting speed by up to 15% | Enhances accuracy by decreasing cut errors |

| Calibration Check | Weekly | Ensures optimal machine settings, reduces downtime | Maintains cuts within a tolerance of ±0.1mm |

| Software Updates | Monthly | Improves cutting algorithms and speeds | Refines edge quality and reduces fraying |

| Cleaning Machine Components | Bi-weekly | Prevents build-up that can hinder performance | Ensures consistent cut quality across all materials |

| Inspection of Wiring and Connections | Monthly | Reduces risk of electrical failures | Maintains consistent power supply for precision cutting |

Employing advanced software in your PPF cutting machine can significantly enhance both efficiency and precision. Modern software solutions provide user-friendly interfaces that allow for intricate design patterns and accurate measurements, ensuring that even the most complex cuts can be executed flawlessly. These programs often come equipped with features like automatic calibration and customizable settings, which adapt to the specific needs of various materials and design intricacies.

Furthermore, the integration of AI technology within cutting software can lead to remarkable improvements in design accuracy and speed. For instance, AI algorithms can analyze user input and make real-time adjustments, optimizing cutting paths to reduce waste and improve output. With such advancements, crafters can focus more on their creative processes while relying on technology to deliver consistent quality in every project. Investing in the right software not only bolsters productivity but also unlocks new levels of creativity, allowing users to expand their crafting potential.

To enhance the efficiency and precision of PPF cutting machines, training operators is crucial. Operators should be equipped with the right techniques to maneuver the machine effectively, which starts with understanding the software and hardware components. Regular training sessions that cover both theoretical knowledge and practical skills can significantly improve their cutting abilities. Familiarity with the machine's settings and features allows operators to optimize performance while reducing the likelihood of errors.

Additionally, developing a strong sense of timing and hand-eye coordination is vital for increasing cutting speed. Operators should practice consistent workflows and learn to anticipate the machine's movements to make quicker adjustments. Engaging in group training exercises can foster a competitive yet supportive environment, further motivating operators to refine their skills. Implementing feedback loops, where operators can share insights about their experiences or difficulties, can also lead to better methodologies and enhance overall cutting proficiency.