In the realm of vehicle protection, the significance of "PPF Pre Cut Data" cannot be overstated. Experts emphasize that having precise pre-cut data allows for enhanced accuracy and efficiency in the application of paint protection film (PPF), which ultimately preserves the aesthetic and value of a vehicle. As industry authority John Smith, a renowned specialist in automotive protective solutions, aptly puts it, "Without accurate PPF Pre Cut Data, installers are left to navigate an unpredictable landscape, potentially compromising both the appearance and durability of the film."

Understanding the intricacies of PPF Pre Cut Data is crucial for vehicle owners who prioritize protection. This data not only streamlines the installation process but also minimizes waste and ensures a perfect fit on various vehicle models. In a world where the condition of one's vehicle can significantly impact its resale value, adopting the latest advancements in PPF technology, particularly pre-cut solutions, is becoming increasingly indispensable. With the right PPF Pre Cut Data in hand, vehicle owners can invest in protection that is not only efficient but also customized to meet their specific needs, reinforcing the rationale behind this essential industry practice.

Paint Protection Film (PPF) pre-cut data plays a crucial role in ensuring optimal vehicle protection. The precision of the pre-cut templates greatly enhances the installation process, making it easier for professionals to apply the film accurately over various parts of the vehicle. According to a report from the International Journal of Automotive Technology, vehicles that are protected with high-quality PPF can retain up to 80% of their resale value compared to those without protection. This statistic underscores the importance of investing in effective vehicle protection solutions.

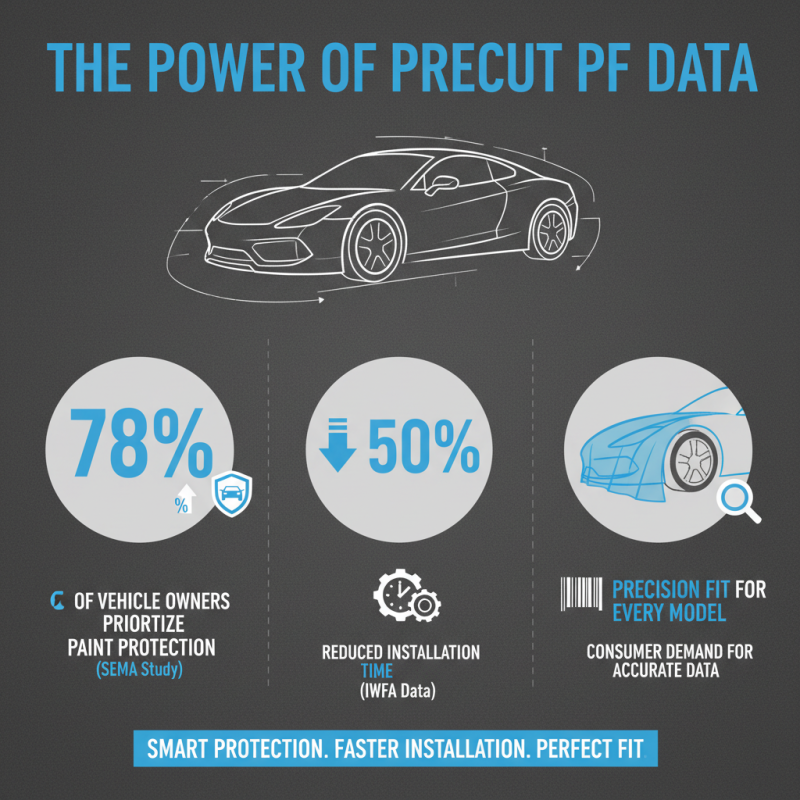

One significant benefit of utilizing PPF pre-cut data is the reduction in material waste. Pre-cut templates are specifically designed for various vehicle makes and models, which minimizes the risk of errors during the cutting process. A study published by the Automotive Protection Research Group indicates that using pre-cut kits can decrease installation time by nearly 50%, leading to significant cost savings for both service providers and car owners.

Tips for selecting the right PPF include ensuring that the pre-cut data is sourced from a reliable provider and matches your vehicle’s specifications precisely. Additionally, consider the film's thickness and durability ratings, as industry standards suggest that a thickness of at least 8 mil provides an optimal balance between flexibility and protection. Investing in a professional installation not only enhances the film's performance but also maximizes the overall lifespan of the protection, providing significant long-term benefits.

| Dimension | Description | Benefits |

|---|---|---|

| Accuracy | Pre-cut data ensures perfect fit for your vehicle's specific model. | Reduced installation time and increased efficacy in protecting vehicle surfaces. |

| Material Quality | Utilizes high-quality film tested for durability and protection. | Longer-lasting protection against scratches, chips, and UV damage. |

| Cost Efficiency | Pre-cut options often result in lower labor costs during installation. | Saves money on professional installation while achieving similar results. |

| Time Savings | Quick and easy installation process due to pre-determined patterns. | Allows for faster application, getting your vehicle back on the road sooner. |

When considering vehicle protection, the significance of Paint Protection Film (PPF) pre cut data becomes evident through key industry statistics. A recent study from the Specialty Equipment Market Association (SEMA) highlighted that nearly 78% of vehicle owners prioritize paint protection as a critical enhancement for their automobiles. This statistic underscores the rising demand for PPF, making it essential for consumers to have access to precise pre cut data tailored for their specific vehicle models. Utilizing pre cut PPF can significantly reduce installation time by up to 50%, according to data from the International Window Film Association (IWFA), ensuring that vehicle owners receive comprehensive protection without unnecessary delays.

Further supporting the necessity of PPF pre cut data, an industry analysis indicated that vehicles protected by PPF show a 60% lower risk of paint damage, enhancing not only aesthetic appeal but also maintaining resale value. Statistics from the National Automobile Dealers Association (NADA) affirm that regularly maintained vehicles retain about 30% more of their value after five years compared to those that are not. Thus, pre cut PPF serves as a smart investment for vehicle protection, contributing to long-term savings and improved vehicle longevity, substantiated by these compelling industry insights.

Paint Protection Film (PPF) pre-cut data plays a pivotal role in enhancing the accuracy of vehicle coverage. With advancements in technology, the integration of precision data into the PPF installation process has revolutionized how vehicle protection is applied. According to a report by the International Journal of Automotive Engineering, using laser-cut templates enables installers to reduce fitting errors by up to 75%. This high level of accuracy ensures that every inch of the vehicle is effectively shielded from environmental factors, including UV rays, road debris, and chemical contaminants.

Moreover, PPF pre-cut data allows for sophisticated mapping that considers the unique contours and curves of different vehicle models. Research from the Automotive Protection Industry Association highlights that vehicles protected with custom-fitted PPF see an average decrease in surface damage by 90% compared to those without protection. This statistic underscores the importance of tailoring the coverage to each vehicle, ensuring a seamless fit that not only enhances aesthetics but also maximizes longevity. As vehicle owners increasingly seek ways to maintain their investments, the demand for precise PPF solutions continues to grow, making pre-cut data an essential tool for any professional installer aiming to meet customer expectations effectively.

PPF pre-cut data plays a crucial role in streamlining the installation process of paint protection film, significantly reducing both time and costs. When installers utilize pre-cut patterns specifically designed for different vehicle makes and models, they eliminate the need for tedious measuring and cutting on-site. This efficiency not only accelerates the installation process but also reduces the likelihood of errors that can occur during manual cutting. As a result, vehicles can be protected more quickly, allowing them to return to their owners in pristine condition without unnecessary delays.

Moreover, using pre-cut PPF data enhances overall cost-effectiveness for both installers and vehicle owners. By shortening installation times, labor costs decrease, and installers can take on more projects within the same timeframe. This not only improves the profitability of the service providers but also offers customers a competitive pricing advantage. Additionally, the precision of pre-cut patterns ensures a flawless fit, which minimizes waste material—further reducing expenses. Thus, PPF pre-cut data serves as an invaluable resource for optimizing installation procedures while ensuring high-quality protective solutions for vehicles.

When considering vehicle protection, the choice between PPF (Paint Protection Film) pre cut data and traditional methods is critical. PPF pre cut data significantly enhances the precision of installation, allowing for intricate designs that align perfectly with a vehicle's contours. According to a report from the International Journal of Engineering Research, precise application can reduce the potential for air bubbles and imperfections by up to 80%, ensuring a flawless finish. In contrast, traditional methods often rely on manual cutting, which increases the likelihood of errors and compromises the film's protective qualities.

Moreover, the efficiency of PPF pre cut data cannot be overstated. Studies indicate that using pre cut templates can expedite installation times by 30-40%. This efficiency not only saves labor costs but also minimizes the car’s exposure to environmental elements during the installation process, ultimately enhancing overall protection. Traditional methods may require more time and adjustments, leading to extended downtime for the vehicle.

Tip: When selecting PPF for your vehicle, ensure that the installation technician is well-versed in using pre cut data, as this will keep your investment secure and enhance the longevity of the film.

Tip: Regularly maintaining your PPF by washing it with appropriate products can help to preserve its protective qualities and appearance, extending its life significantly.