A Ppf Machine is an essential tool for various industries. It plays a crucial role in protective film application. This machine helps to apply protective films on surfaces of vehicles, furniture, and more.

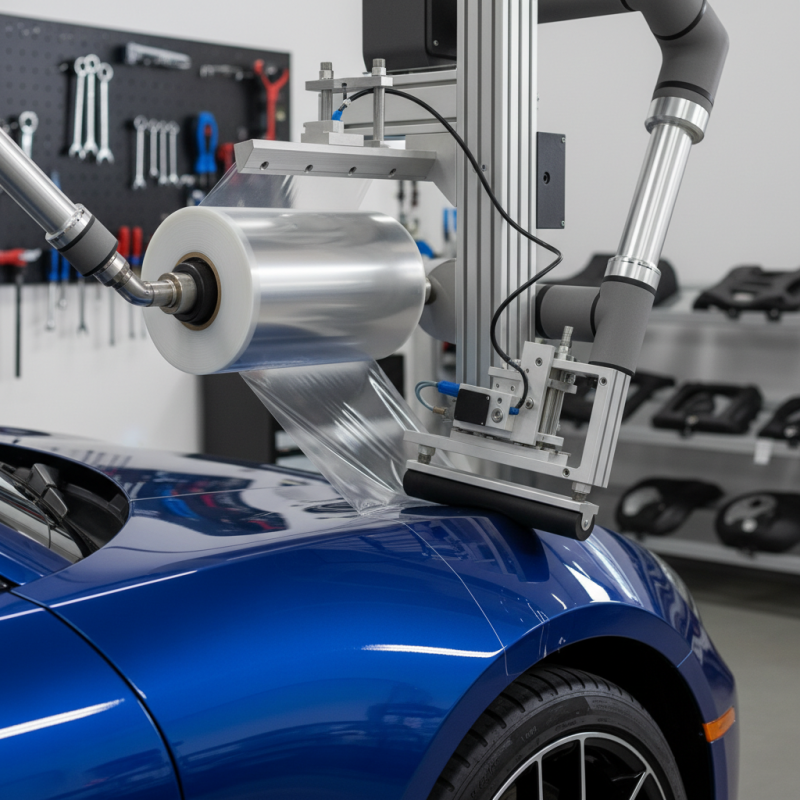

Understanding how a Ppf Machine operates can be fascinating. It typically utilizes heat and pressure to ensure a tight bond. Users often wonder about the effectiveness of this technology. Some might even experience challenges in achieving perfect results.

The Ppf Machine is known for its efficiency, but perfection is hard to attain. Many users may face issues with adhesion or wrinkles in the film. This leads to reflections on improving techniques and equipment. The journey with a Ppf Machine is as important as the final output.

A PPF machine is an advanced tool used in the application of paint protection film. This technology helps preserve the finish of vehicles, protecting them from scratches and environmental damage. The film is strong yet nearly invisible, maintaining the aesthetic appeal of your car.

When considering a PPF machine, accuracy is key. Applying film requires precision. Bubbles and wrinkles can occur if not handled well. Proper setup and calibration of the machine can prevent these issues. Always test on a small area first.

Tips: Clean the vehicle surface thoroughly before application. Dust and dirt can ruin the film's adhesion. Use a squeegee to smooth out bubbles. Over time, some users find that maintenance is necessary. It's vital to regularly inspect the film for any signs of wear or damage. This ensures long-lasting protection.

| Feature | Description |

|---|---|

| Machine Type | Computerized PPF cutting machines |

| Working Mechanism | Uses CAD software to design patterns followed by a cutting plotter |

| Material Used | Clear polyurethane film, some have self-healing properties |

| Applications | Automobile protection, architectural surfaces, electronic devices |

| Benefits | UV protection, scratch resistance, maintains finish integrity |

| Installation Method | Application of heat and pressure during installation for adhesion |

| Maintenance | Regular washing, avoid strong chemicals for cleaning |

| Lifespan | Typically lasts 5-10 years depending on environment and care |

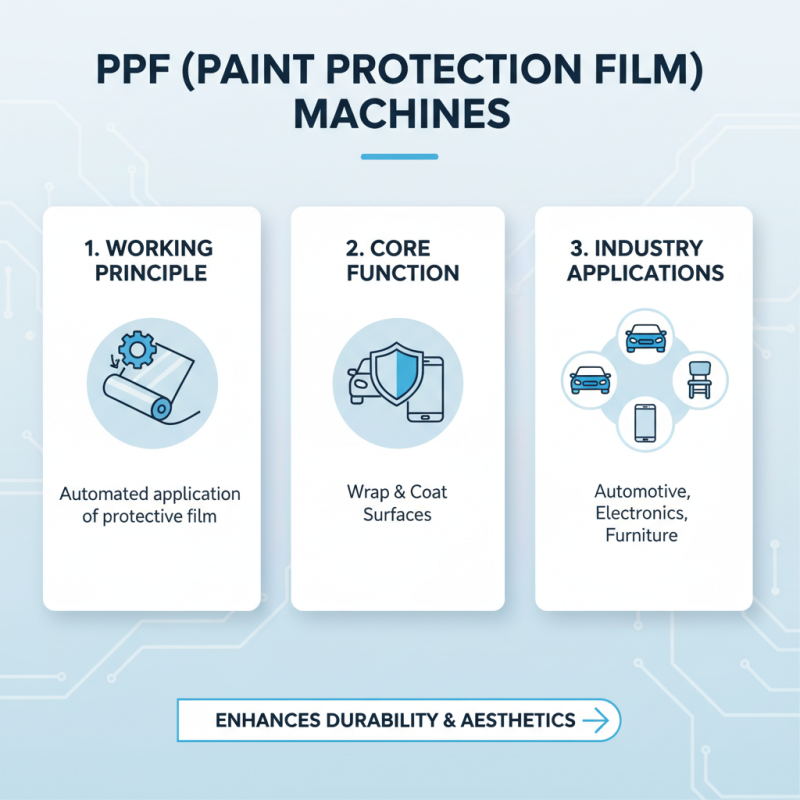

PPF machines are fascinating tools in the world of material processing. Their design is centered around a simple yet effective working principle. At a basic level, these machines are responsible for wrapping or coating surfaces with a protective film. This film enhances durability and aesthetic appeal, serving various industries like automotive, electronics, and furniture.

The process begins with the feed mechanism, where the material is securely held in place. Next, the film is unrolled and heated to ensure proper adhesion. This step is crucial; if the temperature is too high, it may damage the film. Operators need to monitor the machine closely to avoid such mishaps. After the film is applied, pressure rollers help ensure a tight bond. However, achieving the perfect wrap can be challenging. Flaws may occur if the operator does not adjust the tension correctly.

Others might overlook the importance of calibration. A lack of precision can lead to uneven coverage. Cleaning and maintenance should not be neglected, as debris can affect performance. Just like in any technology, imperfections reveal the learning curves in operating PPF machines. It’s essential to stay vigilant in refining the process while embracing the occasional errors as opportunities for improvement.

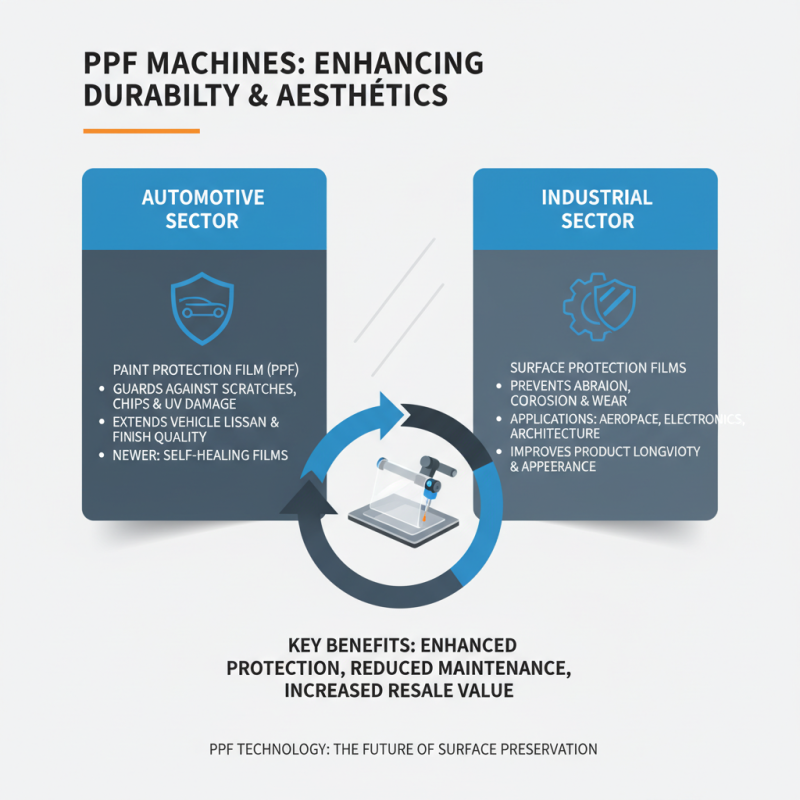

PPF machines play a crucial role in automotive and industrial sectors. These devices apply protective films to surfaces, enhancing durability and aesthetics. In the automotive industry, PPF machines are vital for applying paint protection films to vehicles. Such films guard against scratches, minor impacts, and environmental damage, extending the lifespan of car finishes.

According to industry reports, the global demand for PPF has surged, with a projected annual growth rate of 12% through 2026. This reflects an increasing recognition of the value of surface protection. In industrial applications, PPF machines are used on machinery and equipment to prevent wear and tear. A sturdy protective film can significantly reduce maintenance costs by minimizing damage from abrasion and corrosive substances.

However, there are limitations to consider. Not all PPFs offer the same level of protection against UV rays or chemicals. Users may encounter issues if films are applied incorrectly. Even small bubbles can compromise film integrity. Proper training and attention to detail are critical in ensuring optimal results with PPF machines. As the market continues to evolve, advancements in film technology also present new challenges for users.

When discussing PPF machines, understanding their specifications and industry standards is crucial. PPF, or Paint Protection Film, is vital for vehicle maintenance. Machines must meet certain criteria for effectiveness. They should provide precise cutting capabilities. This ensures that the film fits perfectly on surfaces. Any misalignment can lead to gaps, which defeats the purpose.

Quality standards often dictate how these machines operate. The thickness and type of film they can handle matter significantly. Machines should manage both clear and tinted films. These variations bring unique challenges. Not all machines perform equally under different conditions. It's essential to assess the machine's ability to withstand heat and pressure. A standard operation involves temperature control to avoid film distortion.

Tip: Always check user reviews before purchasing a PPF machine. Feedback from other users can highlight any flaws.

Another aspect is durability. How long a machine lasts is often overlooked. Machines with lower build quality may fail sooner. Regular maintenance is required for optimal functioning. Neglecting this may lead to performance issues.

Tip: Schedule routine checks to ensure everything runs smoothly. Small adjustments can prevent larger problems later.

The paint protection film (PPF) market is experiencing significant growth. According to industry reports, the market is expected to reach approximately $500 million by 2025. This growth is driven by rising vehicle customization trends and increased awareness of automotive protection. Consumers are prioritizing the longevity of their vehicles, prompting more people to invest in PPF technology.

Recent advances in PPF technology include self-healing properties and enhanced durability. These features attract both car enthusiasts and everyday drivers. A survey indicated that 65% of consumers find value in protecting their vehicles from scratches and environmental hazards. However, the challenge remains in educating consumers about the various options available and their respective benefits.

Tip: When considering PPF, evaluate the installation process. Amateur application can lead to imperfections. Ensuring a professional installation enhances durability and appearance.

As the PPF market evolves, sustainability will be vital. Companies are exploring biodegradable films and eco-friendly adhesives. Yet, there is a strong push for innovation alongside environmental responsibility. The balance between high performance and sustainability needs careful consideration. Such choices impact both customer satisfaction and brand reputation.