In the world of automotive customization, achieving the best results with Ppf Cutting Data is essential. This data serves as a foundation for every professional installer. However, many are unaware of the nuances that can impact their outcomes. A flawless wrap can elevate a vehicle's appearance, but mistakes can lead to costly reworks.

Understanding Ppf Cutting Data goes beyond basic measurements. It involves recognizing the unique contours of each vehicle. The accuracy of this data can determine the success of the installation. Yet, even experienced professionals sometimes overlook this point. Small discrepancies can result in poorly fitted film, affecting longevity and aesthetics.

Moreover, optimizing Ppf Cutting Data requires constant reflection and adaptation. Many installers may find themselves stuck in their methods. Continually assessing techniques can unveil new strategies. This pursuit of improvement ensures that every cut is precise. Ultimately, the goal is to enhance both the process and the finished product. Getting it right means being dedicated to the craft.

When discussing PPF cutting data, understanding its significance is crucial. PPF, or paint protection film, helps maintain vehicle aesthetics. Accurate cutting data ensures optimal application and fit. It allows installers to maximize material usage and minimize waste. Each vehicle shape is different, so precise templates are essential. Misalignment can lead to inefficiencies, resulting in unsatisfactory finishes.

One common issue is underestimating the complexity of curves and edges. Installers may not pay enough attention to detailed measurements. This often results in gaps or overlaps. Templates should be double-checked for accuracy to prevent unnecessary rework. Regularly reviewing past projects can highlight recurring mistakes. Keeping a detailed log of cutting data can lead to improvements over time.

Another aspect to consider is the technology used. While modern software simplifies the cutting process, human error remains a factor. New installers may struggle with software nuances. It’s important to practice and familiarize oneself with tools. Taking the time to understand the integration between data and application yields better results. Simple adjustments based on past experiences can lead to significant improvements in the final product.

| Dimension | Recommended Value | Importance | Notes |

|---|---|---|---|

| Blade Depth | 0.5 mm | Ensures clean cuts | Adjust depth based on material |

| Cut Speed | 30 mm/s | Minimizes material stress | Test different speeds |

| Pressure Setting | 150 g | Improves cut quality | Adjust per material type |

| Weed Lines | Recommended after cutting | Facilitates easy removal | Consider complexity of design |

| Software Settings | Latest version | Supports optimal cutting | Check for updates regularly |

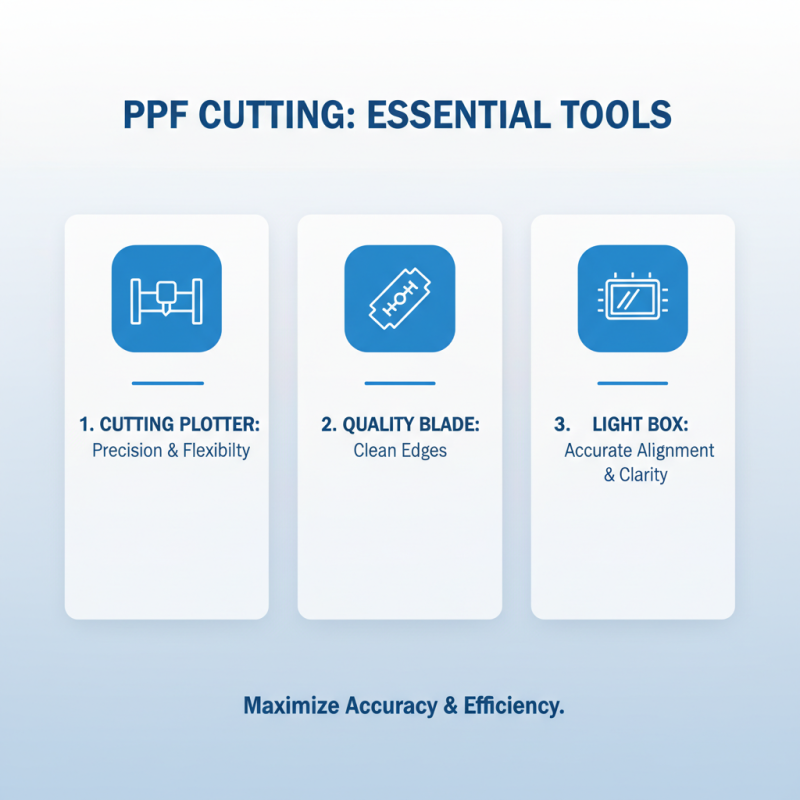

When it comes to PPF cutting, having the right tools can make a significant difference. A quality cutting plotter is essential. It should offer precision and flexibility. A good blade is critical too. It needs to create clean edges without snagging the film. Sometimes, users overlook the importance of a light box. This tool can help see the film clearly, ensuring accurate alignment.

In addition to these, you'll need various other items. A reliable workstation is essential. A clean surface prevents dust from affecting the film. Have a straight edge and a cutting mat on hand. These items will help maintain straight cuts. While many focus on high-tech tools, simple items often get dismissed. Sometimes, a sharp utility knife or scissors can do the job well.

Remember, mistakes happen. It's easy to misalign the film or apply too much pressure. These errors can lead to wasted material. Always take your time, and don't rush the process. Reflecting on past projects can help improve your technique. Evaluating what went wrong helps avoid future mistakes.

Preparing PPF cutting data can be intricate. It requires attention to detail and a systematic approach. Start by gathering all necessary templates. Ensure they are accurate and up-to-date. Use precise measurements. This helps in preventing errors during the cutting phase.

When preparing your data, keep your workspace tidy. Clutter can lead to mistakes. Verify your templates multiple times. A simple error can ruin an entire project. You might face setbacks, but these moments are learning opportunities.

Tip: Always do a test cut on scrap material before finalizing. This ensures optimal accuracy. Remember to check blade settings. A dull blade may not yield clean cuts. Another tip is to adjust pressure settings based on the material thickness. Each material behaves differently. Testing will save time and frustration.

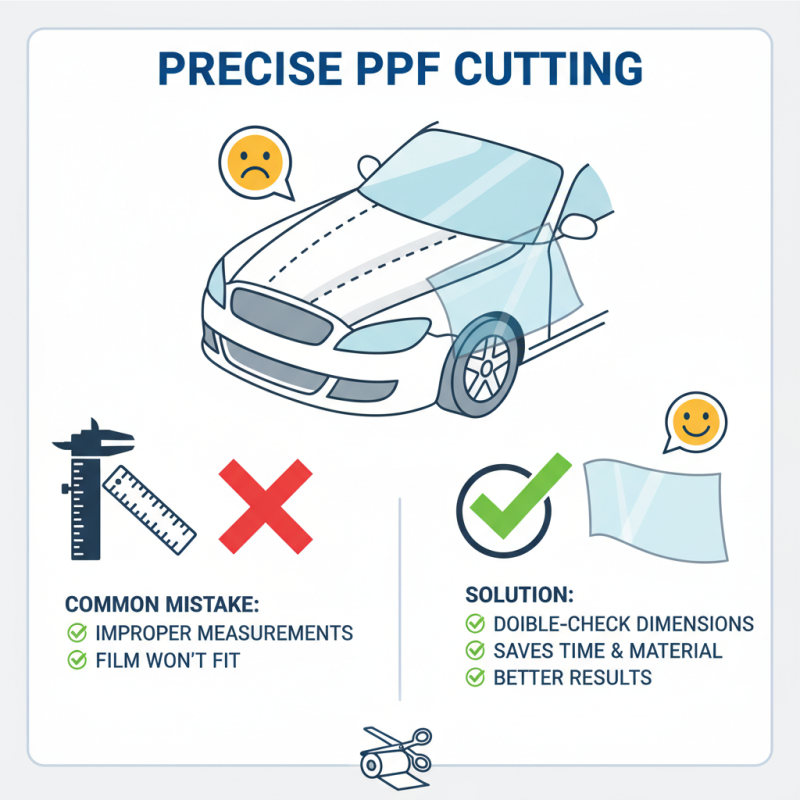

PPF cutting can be tricky. One common mistake is improper measurements. If the dimensions are not accurate, the film will not fit well on the vehicle. Always double-check your measurements before you begin cutting. This can save time and material, leading to better final results.

Another frequent error involves uneven cutting pressure. Too much force can cause the blade to slip, while too little can lead to jagged edges. Aim for a steady hand to maintain consistent pressure. Taking breaks can help reduce fatigue and maintain precision. A clean workspace also minimizes distractions and mistakes.

It's important to remember that not every cut will be perfect. Mistakes can happen to the best of us. The key is to learn from each experience. Use remnants for practice. This can improve your skills over time. Reflect on what went wrong and adjust your technique accordingly. Consistent practice will lead to better outcomes.

When working with PPF (Paint Protection Film), adjusting cutting data for various surfaces is crucial for quality results. Different surfaces, such as curved or textured ones, require specialized approaches. It's important to analyze each surface carefully before cutting the film.

One effective tip is to test your cutting data on a small area first. This allows you to see how the film adheres to the surface. If bubbles or wrinkles appear, the data may need adjustments. Fine-tune the pressure settings on your cutting machine for better outcomes.

Another useful tip involves paying attention to surface materials. For instance, matte finishes might require a softer touch, while glossy surfaces can handle firmer pressure. Experimenting with different settings will help you find the right balance. Don't hesitate to document your findings—this will help in future projects, reducing trial-and-error time.