When it comes to window tinting, a Ppf Cutter is essential. This tool ensures precise cuts for paint protection films, enhancing the overall appearance and durability of your vehicle. Selecting the right Ppf Cutter can be overwhelming. There are various options available on the market, each with unique features. Factors like blade quality, ease of use, and design play a crucial role in your decision.

However, it's not simply about choosing the most popular Ppf Cutter. You need to understand how it fits your specific needs. Some cutters may excel in certain areas but lack in others. It's important to recognize this balance. A high-end Ppf Cutter might not always be the best fit for everyone. Reflection on your own requirements will guide your choice.

Ultimately, investing in a reliable Ppf Cutter can save time and effort. A good quality cutter can minimize mistakes during installation. While perfection may seem the goal, every user may experience challenges with their chosen tool. Embracing the learning curve can lead to better results in the long run.

A PPF cutter is a specialized tool designed for applying paint protection film on vehicles. Its primary role involves cutting sheets of PPF to fit various surfaces of an automobile. This film safeguards the paint from scratches, rocks, and other environmental hazards. Using a PPF cutter efficiently can make a significant difference in the installation process. The precision of the cut ensures that the film adheres smoothly without wrinkles or bubbles.

When choosing the best PPF cutter, consider its ease of use and cutting accuracy. Some models come with software to help design templates for your specific vehicle. This can save time and improve the overall look of the installation. However, not all cutters are user-friendly. It can be frustrating to figure out complex settings. A trial-and-error approach might be necessary, which can lead to less-than-perfect cuts.

Additionally, the blade quality is crucial. Sharp blades provide clean edges, while dull ones can ruin your project. Regular maintenance is necessary to ensure longevity. Investing in the right cutter can elevate your vehicle protection game, but it's important to understand your specific needs. Sometimes, it may take a few attempts to achieve the desired results.

When choosing a PPF cutter, several key features must be considered. One crucial aspect is the cutting width. A wider cutting width allows for larger sheets, saving time and effort during applications. However, a cutter that is too large might be cumbersome. Balance is essential, as a compact design can also streamline the process in tight spaces.

Another vital feature is the software compatibility. A user-friendly interface makes design work easier. Look for cutters that support various file formats. This flexibility enhances creativity and efficiency. Additionally, check the speed of the cutter. Faster machines can handle more projects, but they may lack precision. It’s important to find a cutter that offers both speed and accuracy for effective results.

Lastly, durability is crucial. A sturdy design will withstand frequent use. Replaceable blades are also beneficial, extending the cutter's life. Many users overlook maintenance needs. Reflect on how often the machine will be used before choosing. Balancing these features can lead to a more satisfying experience.

When considering PPF (Paint Protection Film) cutters, understanding the types available is crucial. There are mainly two options: manual and electric. Manual cutters rely on human precision. They are straightforward and cheaper. However, they may lack the speed and consistency found in electric cutters. If you enjoy hands-on work, a manual cutter might be appealing. But it can be tiring if you have large projects.

Electric PPF cutters, on the other hand, offer efficiency. They cut through films quickly and uniformly. This can save a significant amount of time. Many users appreciate the accuracy and reduced fatigue that comes with electric models. However, they often come at a higher price point. Not everyone may find them easy to use. Understanding your needs is essential when choosing between these options. Reflect on how often you’ll use it and the types of projects you undertake.

Choosing the right PPF cutter involves careful thought. Both options have pros and cons. A manual cutter gives you control, but expect some inconsistencies. An electric cutter speeds up the process but may feel overwhelming for beginners. Each user must weigh their comfort level against their cutting needs.

When choosing a PPF cutter, quality and durability are key factors. A good cutter should feel sturdy in your hand. Check the materials used. High-quality stainless steel is generally preferred. Look for a blade that retains its sharpness after multiple uses. Dull blades lead to mistakes and wasted resources.

Consider the handle design as well. It should offer comfort and grip. Ergonomics matter significantly during long projects. Additionally, weigh the cutter; a heavier model might provide better control during use. However, if it's too heavy, fatigue could set in quickly. Each individual's preference can vary, so it might take testing a few options before finding the right one.

Don’t overlook the manufacturer’s warranty. A longer warranty period often indicates confidence in the product's durability. Pay attention to user reviews as well. They can highlight potential issues that specs do not cover. What works for one person might not work for another. Therefore, it is essential to reflect on your own needs and experiences.

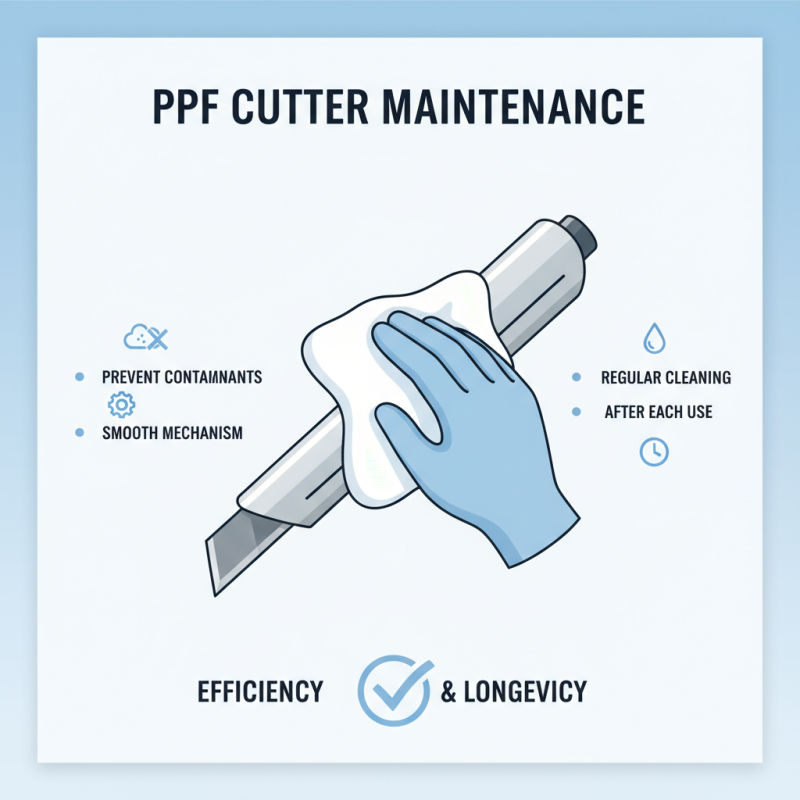

Maintaining your PPF (Paint Protection Film) cutter is crucial for efficiency and longevity. Regular cleaning is essential. Dust and debris can jam the blade, affecting performance. After each use, wipe down the cutter with a soft cloth. This simple act helps keep the mechanism smooth.

In a recent industry report, over 30% of professionals noted that improper maintenance shortens the lifespan of their tools. It's not just about cleaning. Calibration matters, too. A poorly calibrated cutter can lead to inaccurate cuts, resulting in wasted materials and time. Take a moment to adjust the blade height accurately.

Using the right technique can greatly enhance the overall experience. Ensure you apply consistent pressure while cutting. This reduces the chances of tearing the film. Also, consider the angle of the cutter as it slides along the material. An awkward angle can lead to uneven edges. Often, users overlook these fine details, leading to frustration and subpar results. Addressing these factors can make a significant difference in your workflow.