In the ever-evolving world of automotive care, the Ppf Cut Program has emerged as a revolutionary approach to vehicle protection. As vehicles continue to face environmental challenges and potential hazards on the road, the need for effective protective solutions is more pertinent than ever. Industry expert, John Smith, a leading figure in automotive protective films, emphasizes the significance of this program by stating, “The Ppf Cut Program not only enhances the durability of your vehicle’s exterior but also provides invaluable peace of mind to drivers.”

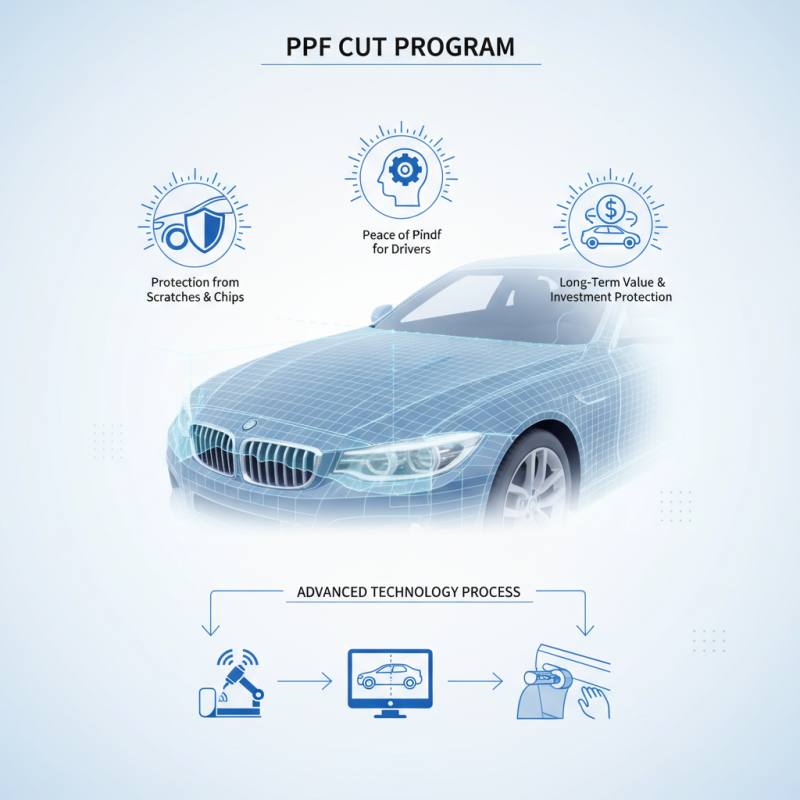

The Ppf Cut Program utilizes advanced technology to deliver precise and custom cuts of paint protection film, ensuring an impeccable fit that shields vehicles from scratches, chips, and other damaging elements. This innovative solution caters to a variety of car models and surfaces, allowing owners to maintain their vehicles in pristine condition. With the growing popularity of this program, many car enthusiasts and everyday drivers are discovering its benefits and the long-term value it adds to their investment.

By understanding how the Ppf Cut Program works and the advantages it offers, vehicle owners can make informed decisions to enhance their automobile's longevity. As protective technologies advance, embracing solutions like the Ppf Cut Program can lead to better protection and preservation for one of life's essential assets: our vehicles.

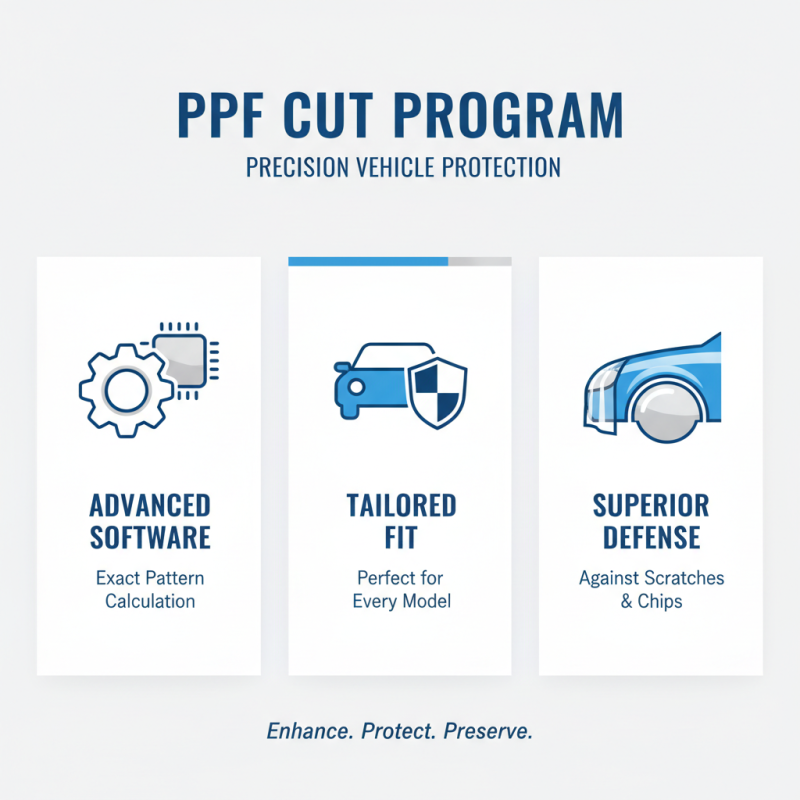

The PPF Cut Program, or Paint Protection Film Cut Program, is a specialized service designed to enhance the protective capabilities of automotive paint protection films. This program involves precise cutting techniques that utilize digital templates tailored to specific vehicle models. By leveraging advanced software, technicians can produce exact patterns that ensure optimal coverage for various surfaces of the vehicle, protecting it from scratches, chips, and environmental damage.

One of the primary benefits of the PPF Cut Program is that it minimizes the risk of human error during installation. With custom-cut films, installers can achieve a seamless fit that enhances both the aesthetics and functionality of the protection. This results in a smoother application process and a more durable outcome, as the film is less likely to lift or peel over time. Additionally, the program is designed for efficiency, meaning quicker turnaround times for vehicle owners looking to safeguard their investments without sacrificing quality.

PPF cutting technology represents a significant advancement in vehicle protection, utilizing precise measurements and automated processes to deliver custom-fit paint protection film (PPF). This technology begins with digital templates that are created using advanced software to measure the contours and dimensions of a vehicle. By employing computer numerical control (CNC) machines, this process ensures that the PPF is cut with extreme accuracy, allowing for seamless application over various surfaces of the car.

One of the key benefits of PPF cutting technology is its ability to minimize waste while maximizing coverage. Since the film is tailored specifically to each vehicle model, it reduces the risk of human error during the cutting process and ensures optimal use of the material. Furthermore, this precision allows for a cleaner installation, resulting in a PPF that adheres more effectively and provides better protection against chips, scratches, and other environmental hazards. As a result, vehicle owners can enjoy enhanced longevity of their car's exterior, making PPF cutting an invaluable component of modern vehicle aesthetics and maintenance.

The PPF Cut Program, or Paint Protection Film Cut Program, is a revolutionary method designed to enhance vehicle protection through precision engineering. By utilizing advanced software technology, the program calculates the exact patterns needed for the paint protection film, ensuring a perfect fit for every vehicle model. This tailored approach allows for significant coverage against scratches, chips, and other forms of paint damage, maintaining your vehicle's aesthetic appeal and resale value.

One of the standout features of the PPF Cut Program is its ability to minimize material waste while maximizing coverage. The digital patterns are created to fit snugly around the contours of your vehicle, which not only improves the film's effectiveness but also streamlines the installation process. As a result, owners can expect a quicker turnaround without compromising on quality. By investing in this program, vehicle owners can ensure that their cars are protected from the harsh elements of daily driving, such as road debris and environmental pollutants.

**Tips for Optimal Vehicle Protection:**

1. Regularly clean your vehicle's surface before applying the film to ensure optimal adhesion.

2. Consider having the film professionally installed to guarantee a seamless application, which can enhance durability and performance.

3. Maintain regular inspections to check for any wear and tear on the film, allowing for timely repairs that prevent damage to the underlying paint.

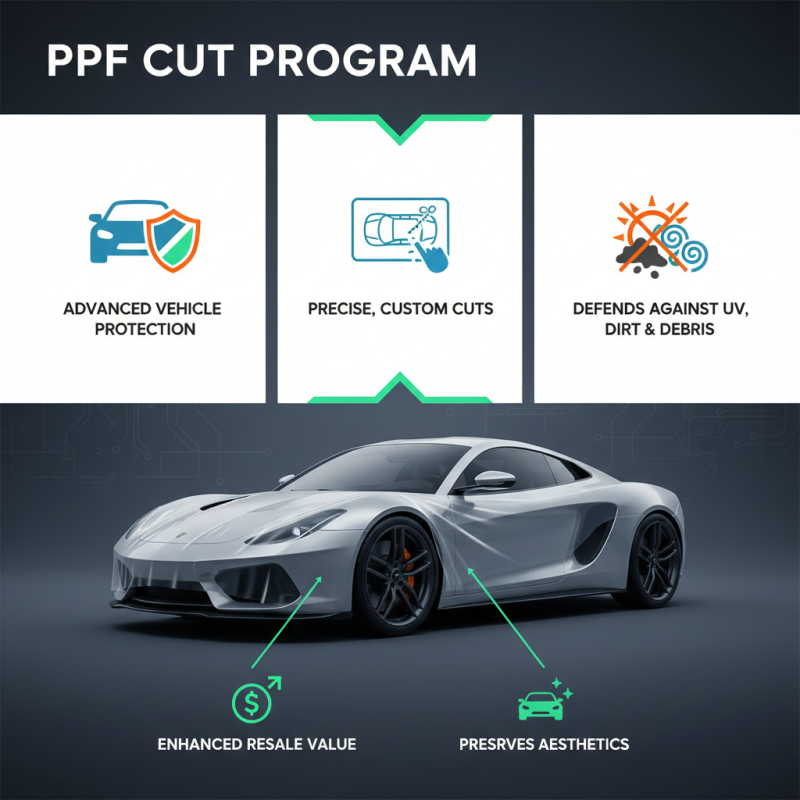

The PPF Cut Program is a revolutionary service designed to enhance the protection of your vehicle's exterior. Utilizing advanced technology, this program produces precise cuts of paint protection film (PPF) that match your vehicle's specific dimensions. One of the key benefits of the PPF Cut Program is its ability to safeguard your vehicle from various environmental hazards like UV rays, dirt, and debris. This added layer of protection not only preserves the aesthetic appeal of your car but also enhances its resale value by preventing damage and wear.

An additional advantage of the PPF Cut Program is the ease of application. With pre-cut patterns tailored to your vehicle, installation becomes a straightforward process, reducing the chances of bubbles or imperfections often found in DIY applications. This means you can enjoy a professional finish that looks immaculate while saving time.

Tips for getting the most out of the PPF Cut Program include choosing a reputable installation service and ensuring that your vehicle is clean and free of contaminants before application. Regular maintenance, such as gentle washing and avoiding harsh chemicals, will help prolong the life of the protection film, ensuring your vehicle remains in pristine condition for years to come. Embrace the benefits of the PPF Cut Program to elevate your vehicle protection and maintain its allure.

When it comes to protecting your vehicle's exterior, two primary methods often come to mind: Paint Protection Film (PPF) and traditional methods like waxing and sealants. While both approaches aim to shield your car from damage, they differ significantly in their effectiveness and longevity. Traditional vehicle protection methods, such as waxing, provide a layer of shine and a short-term barrier against dirt and debris. However, these coatings can wear off quickly due to exposure to the elements, requiring frequent reapplication to maintain their protective qualities.

In contrast, PPF offers a more durable solution. Composed of a clear, thermoplastic urethane material, PPF is designed to absorb impacts from stones, scratches, and other road debris. Unlike traditional wax or sealants that may last only weeks or months, high-quality PPF can withstand years of wear and tear while maintaining its clarity and protective properties. Additionally, PPF is self-healing, meaning minor scratches can disappear with heat, offering a unique advantage over conventional waxes that do not possess this capability. This resilience not only enhances the aesthetic appearance of the vehicle but also preserves its resale value by preventing unsightly blemishes and paint damage.

Ultimately, while traditional vehicle protection methods serve a purpose, they often fall short in providing long-lasting, comprehensive protection compared to PPF. For those seeking a reliable solution that combines durability with aesthetic preservation, PPF stands out as a superior option in the realm of vehicle protection.

| Protection Method | Durability | Cost | Installation Time | Self-Healing Properties | Resale Value Impact |

|---|---|---|---|---|---|

| PPF (Paint Protection Film) | Up to 10 years | $$$ | 2-3 hours | Yes | Positive |

| Ceramic Coating | 2-5 years | $$ | 4-6 hours | No | Neutral |

| Wax | 1-3 months | $ | 1 hour | No | Negative |

| Sealant | 6-12 months | $$ | 1-2 hours | No | Negative |