In the ever-evolving world of design and manufacturing, a Cutting Plotter stands as a transformative tool that has significantly streamlined the way projects are executed. According to industry expert John Doe, "A Cutting Plotter is not just a device; it is a gateway to precision and creativity, allowing artists and designers to bring their visions to life with unmatched accuracy." This sentiment echoes the growing importance of cutting plotters in various sectors, including signage, textile, and graphics, where the demand for exacting cuts and intricate designs is paramount.

Understanding the mechanics of a Cutting Plotter can greatly enhance the efficiency of any project. These machines utilize advanced technology to interpret digital files, translating them into physical cuts on a wide range of materials. The result is a seamless blend of technology and artistry, making it an indispensable asset for professionals seeking to elevate their work. This introduction to the capabilities and functionality of a Cutting Plotter sets the stage for a deeper exploration into how it can revolutionize your projects and drive innovation in your creative endeavors.

A cutting plotter is a precision machine designed to cut materials such as vinyl, paper, and fabrics into specific shapes and designs. Constructed with a blade that moves along the X and Y axes, it can execute intricate cuts based on digital designs created via graphic software. These devices are widely used in various industries, from signage and vehicle graphics to fashion and crafting, enabling users to transform their creative ideas into tangible products with accuracy and efficiency.

When using a cutting plotter, preparation is key. Ensuring that your design files are correctly formatted and that the cutting mat is securely placed can drastically enhance the cutting process. Additionally, selecting the right blade for the material you are working with is vital to achieving clean cuts and avoiding damage to the machine or material.

Tips: Always perform a test cut on a scrap piece of material before proceeding with your final project. This not only saves time and resources but also helps you fine-tune the settings for perfect results. Furthermore, regularly maintaining your cutting plotter—by cleaning the blade and checking for any debris—can prolong its lifespan and ensure consistent performance.

Cutting plotters have revolutionized the way we approach design and fabrication across various industries. At their core, these machines utilize a precision cutting blade that is controlled by computer software to cut materials such as vinyl, paper, and fabric. By following vector graphics and intricate designs, cutting plotters achieve high levels of accuracy and detail. According to a report from the International Sign Association, the cutting plotter market is expected to grow by 4% annually, largely driven by increased demand in signage and promotional material production.

The technology behind cutting plotters involves several key components, including a blade, a stepper motor for movement, and a control system that interprets design files. The blade can be adjusted for depth based on the material being cut, which enhances versatility and efficiency. Many modern plotters also incorporate optical sensors that ensure precise alignment and cutting of complex designs. Additionally, integrating these machines with design software allows for seamless workflow, enabling users to create and edit projects before executing cuts, thus minimizing material wastage.

Tips: When working with cutting plotters, always ensure that your design files are optimized for the specific material you are using. This not only maximizes the machine's capabilities but also extends the life of the blade. Additionally, experimenting with blade settings on scrap materials can help fine-tune your cutting process for optimal results. Consider investing in training for staff to fully leverage the features of the cutting plotter technology, as proper knowledge can greatly enhance productivity.

| Feature | Description | Application |

|---|---|---|

| Precision Cutting | Cuts materials with high accuracy, typically within a margin of 0.1 mm. | Ideal for creating intricate designs in vinyl, paper, and fabric. |

| Material Compatibility | Can cut various materials such as vinyl, cardboard, and thin plastics. | Used in signage, crafts, and prototyping. |

| Software Integration | Works with design software like Adobe Illustrator and CorelDRAW. | Enables users to directly send designs from software to the cutter. |

| Speed | Machines can operate at speeds up to 1000 mm/s. | Useful for high-volume production environments. |

| Ease of Use | User-friendly interfaces with touchscreen controls in many models. | Accessible for both beginners and experienced users. |

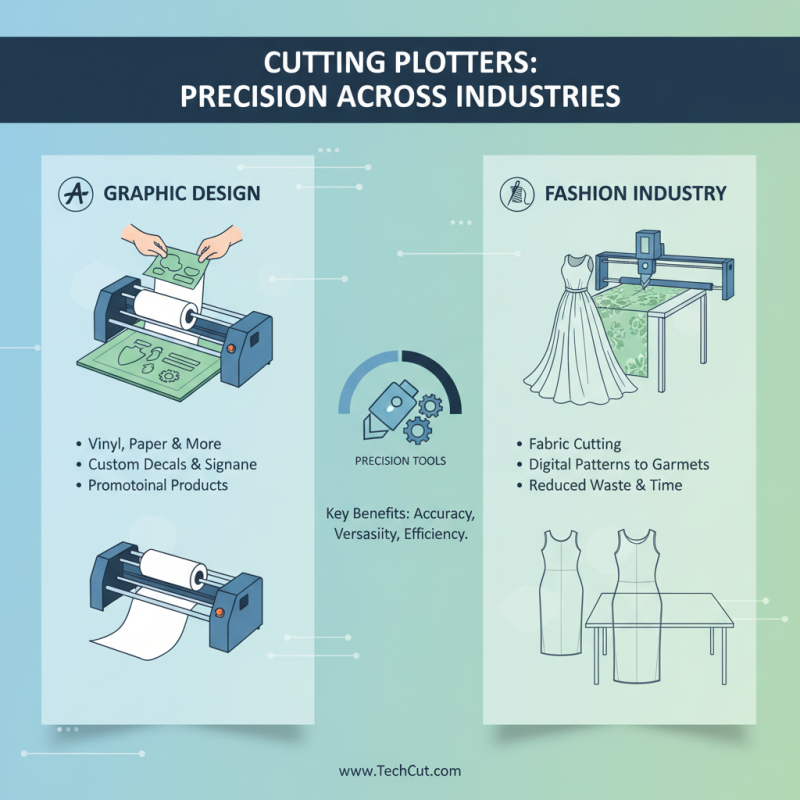

Cutting plotters have established themselves as vital tools across various industries due to their precision in cutting a wide range of materials. In the graphic design sector, they are used for creating intricate designs on vinyl, paper, and other materials, enabling artists to produce customized decals, signage, and promotional products. Similarly, the fashion industry utilizes cutting plotters for fabric cutting, allowing designers to transform digital patterns into physical garments with great accuracy, reducing material waste and production time.

In the automotive and manufacturing fields, cutting plotters play a crucial role in producing patterns for upholstery and parts. These machines ensure that components are cut to exact specifications, which is essential for both safety and efficiency. Additionally, the packaging industry benefits from cutting plotters, as they create prototypes and custom packaging designs, streamlining production processes and meeting unique client demands.

Tips: When selecting a cutting plotter for your projects, consider the materials you will use and the scale of your production. Investing in a high-quality plotter that suits your specific needs can greatly enhance your workflow. Additionally, proper maintenance of the machine is essential to ensure consistent performance and longevity, so always refer to the manufacturer’s guidelines for upkeep.

When it comes to selecting the right cutting plotter for your project needs, there are several factors to consider to ensure optimal performance and efficiency. Firstly, understanding the primary functions of cutting plotters is crucial. These machines are designed to cut various materials such as vinyl, paper, and cardstock with precision, making them essential for industries ranging from signage to crafting. According to the Global Cutting Plotter Market report published by Market Research Future, the industry is projected to grow significantly, driven by advancements in cutting technology and the rising demand in the advertising sector.

One of the key aspects to consider is the size of the cutting area based on the types of projects you intend to undertake. For large-scale manufacturing or commercial applications, a wider cutting plotter can handle bigger media rolls and larger projects efficiently. Conversely, if your focus is on smaller, detailed projects, a compact model may suffice. Additionally, consider the software compatibility of a cutting plotter, as seamless integration with design software can drastically affect workflow efficiency. Recent surveys suggest that about 67% of users prioritize software compatibility when choosing a cutting plotter, emphasizing the need for technology that supports an intuitive design process.

Furthermore, evaluating the cutting force and speed of the plotter is essential for achieving desired results. The cutting force determines the ability to handle different materials, while the speed affects overall productivity. Reports indicate that cutting plotters with adjustable speed settings can improve project turnaround times by up to 30%. As such, investing in a model that offers both versatility and precision is crucial for anyone looking to enhance their project outcomes.

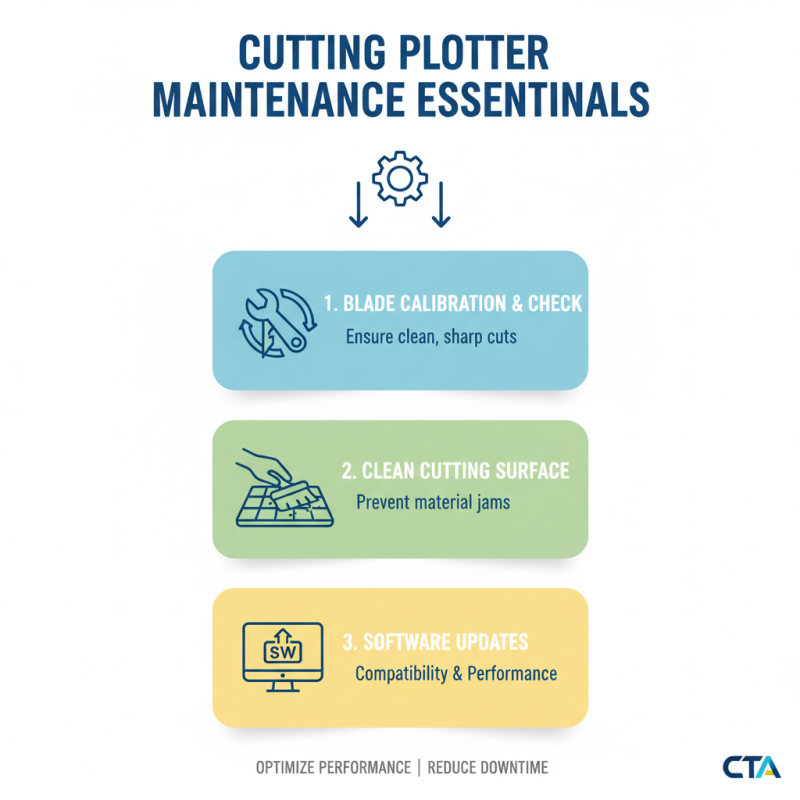

Proper maintenance of cutting plotters is essential for achieving optimal performance and longevity. According to a report by the Consumer Technology Association, over 40% of businesses experience downtime due to equipment malfunctions, which can often be traced back to inadequate maintenance practices. Regularly scheduled maintenance can minimize these risks and ensure a smoother workflow. Key maintenance practices include regularly checking and calibrating the blade, cleaning the cutting surface to remove debris, and ensuring that the software is updated to the latest version for compatibility and improved performance.

Additionally, users should pay attention to the blade's condition, as a dull or damaged blade can lead to uneven cuts and increased strain on the machine, potentially shortening its lifespan. A study conducted by the International Sign Association suggests that properly maintained cutting plotters can improve cutting accuracy by up to 25%, which can significantly enhance production efficiency. It's advisable to keep a maintenance log to track usage patterns and any issues encountered, enabling operators to anticipate potential problems before they escalate. Overall, investing time and effort in regular maintenance not only boosts performance but also protects the investment in cutting plotter technology.