In today's competitive marketplace, selecting the right equipment is crucial for the success of any business, especially in industries that require precision and efficiency. One such essential tool is the Ppf Cutting Machine, which plays a vital role in producing high-quality pre-cut films for automotive and other applications. With various options available, choosing the best Ppf Cutting Machine tailored to your specific business needs can significantly impact your operational efficiency and product quality.

When considering a Ppf Cutting Machine, it's important to evaluate a range of factors, including cutting precision, speed, ease of use, and durability. Understanding your business requirements, such as the volume of production and the types of materials you'll be working with, is essential to make an informed decision. Moreover, assessing the machine's features and technology can ensure that you invest in a solution that meets the demands of your workflow while providing flexibility for future growth. In this guide, we will delve into the key aspects to consider in order to choose the best Ppf Cutting Machine that aligns with your business objectives.

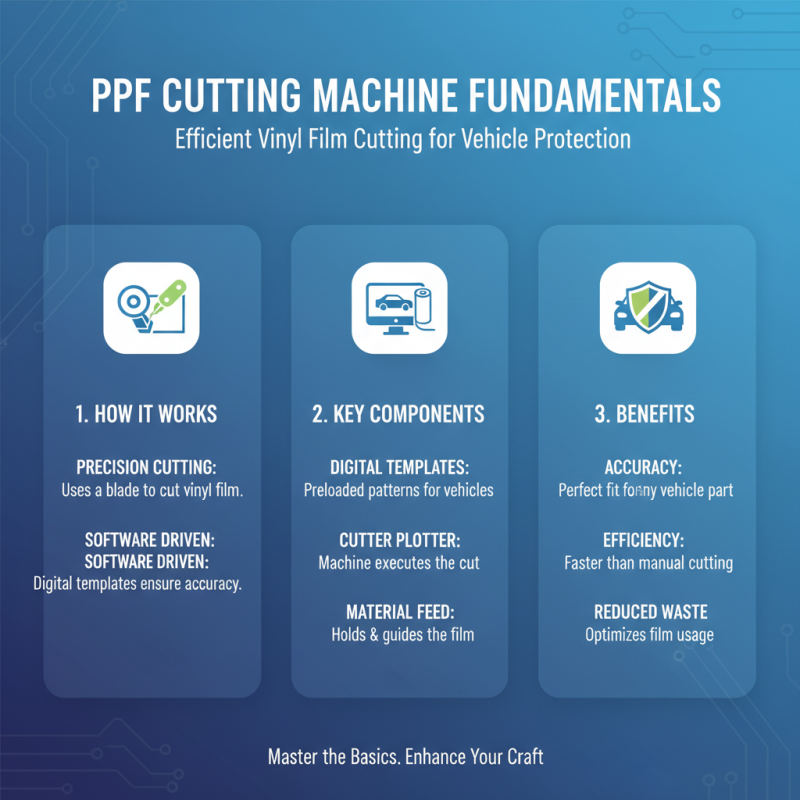

When selecting a PPF cutting machine, it’s essential to understand the fundamentals of how these machines operate. PPF, or Paint Protection Film, cutting machines are designed to efficiently cut vinyl films to the precise dimensions required for vehicle wrapping and protection. These machines use software that comes preloaded with templates for various vehicle models, which allows users to quickly generate accurate patterns. Mastery over these basic functionalities sets the foundation for more advanced usage.

Another crucial aspect to consider is the cutting technology employed by these machines. Most modern PPF cutting machines utilize either blade-based or knife-less cutting methods. Blade-based systems involve physical blades to cut through the film, providing an excellent finish but requiring regular maintenance and blade replacements. Conversely, knife-less cutting techniques utilize a special line that is embedded within the film, which minimizes the risk of damaging the vehicle's surface. Understanding these differences will help businesses align their needs with the right machine to enhance productivity and ensure high-quality results.

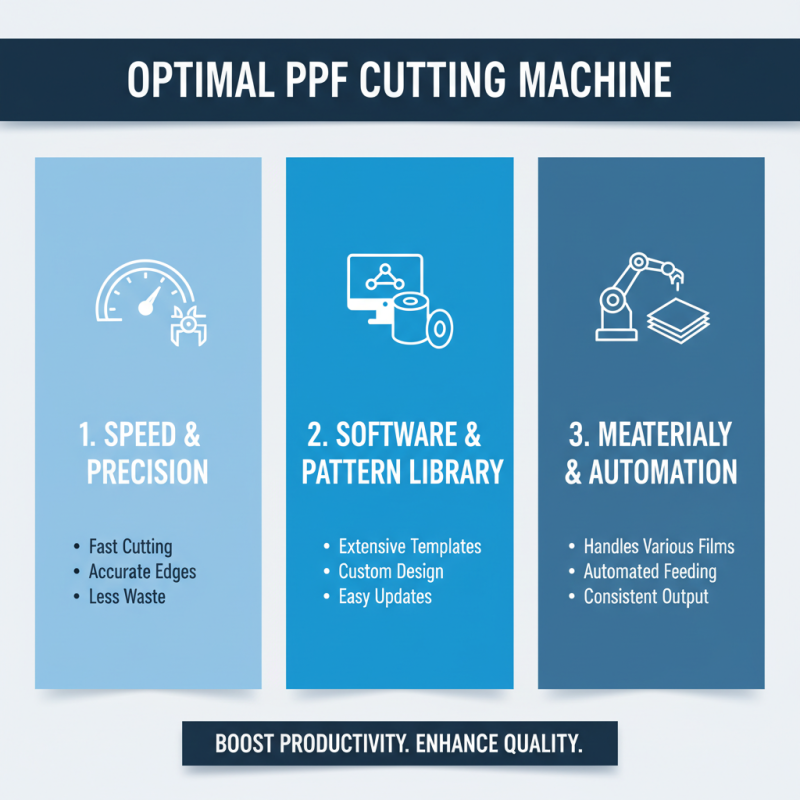

When selecting the best PPF (Paint Protection Film) cutting machine for your business, it’s essential to focus on key features that will enhance your workflow and productivity. One of the primary considerations is the cutting speed and precision. A machine that offers high-speed cutting without sacrificing accuracy will ensure that you achieve clean and precise cuts, thus minimizing waste and improving efficiency.

Another crucial feature to consider is the software compatibility. A user-friendly software interface that integrates smoothly with your design programs is vital for streamlining operations. Look for machines that support various file formats, as this will give you the flexibility to work with different designs and templates easily.

**Tips:** Always check for customer reviews or testimonials regarding the software experience. A machine might boast great hardware, but if the accompanying software is not intuitive, it can hinder your production process.

Additionally, consider the size and space requirements of the cutting machine. Ensure that it fits within your workspace and that you have the necessary room for installation and operation. Machines with adjustable sizes or models that can be easily stored away when not in use can be particularly beneficial for smaller shops.

**Tips:** Measure your workspace and plan where the machine will reside, considering space for material loading and unloading, which often gets overlooked.

When selecting a paint protection film (PPF) cutting machine for your business, evaluating the size and capacity is crucial to ensure it meets your operational needs. The machine's size should correspond to your workspace and the scale of projects you typically handle. If your business focuses on larger vehicles or extensive custom jobs, opting for a machine with a bigger cutting area will enhance your efficiency and allow for seamless film application. Conversely, if your operations are more varied in scope, a compact machine might suffice while still delivering the precision required for intricate designs.

In addition to physical dimensions, assessing the capacity of the cutting machine is key to maximizing productivity. Consider the machine's cutting speed and the thickness of materials it can handle. A machine that can accommodate a variety of material types and thicknesses will provide greater versatility for different customer needs. This flexibility can be especially beneficial for businesses that receive diverse requests, enabling you to adapt quickly without needing multiple machines. Ultimately, aligning the size and capacity of the PPF cutting machine with your specific business requirements will promote smoother operations and better serve your clientele.

This chart illustrates the suitable maximum width of PPF cutting machines based on different business scale options. Small scale businesses may require machines with a maximum width of 24 inches, while medium scale operations benefit from a 36-inch width. Large scale businesses can utilize machines with widths up to 54 inches, and commercial setups typically require machines that can handle 72 inches.

When selecting a PPF cutting machine for business needs, it’s crucial to evaluate the performance of different brands and models. According to a recent industry report published by Smithers Pira, the demand for paint protection films has surged by over 20% in the past few years, making it imperative for businesses to invest in reliable cutting technology that can enhance efficiency and reduce waste. For instance, machines that offer faster cutting speeds and precise calibration can significantly improve the overall production process, allowing for higher output with less material.

Performance metrics such as cutting accuracy, speed, and user-friendly interfaces play a vital role in the selection process. A comparative analysis from a leading market research firm highlighted that models with automated features demonstrate a 30% increase in cutting accuracy, minimizing the need for rework and material waste. Additionally, user feedback indicates that machines equipped with advanced software provide better compatibility with various film types, leading to improved versatility for business operations. As companies aim to optimize their PPF installation services, understanding the technical specifications and real-world performance of each model will be essential in making an informed purchasing decision.

When evaluating the budget and cost-effectiveness of PPF cutting machines for your business, it's essential to consider both initial investment and long-term operational costs. According to a recent market report, the average price for high-quality PPF cutting machines ranges from $3,000 to $10,000, depending on features and capabilities. Investing in a reliable machine may seem steep at first, but the long-term savings on labor and material waste can justify the upfront costs. Businesses can save up to 20% on materials due to more efficient cutting processes, as accurately programmed machines drastically reduce excess material usage.

In addition to direct costs, consider potential ROI based on your service offerings. For example, businesses that accurately assess their pricing strategies can expect an average revenue increase of 15% when they incorporate PPF cutting machines into their services. This increased revenue often stems from the ability to handle a wider range of projects with higher precision. Moreover, understanding the operational efficiency metrics can help you project future savings; a machine that operates at a speed of 20 to 30 feet per minute can significantly reduce turnaround times, allowing for an increase in the volume of jobs completed. Therefore, conducting a thorough analysis of the costs associated with both acquisition and operation of PPF cutting machines is crucial for maximizing financial performance in the long run.

| Machine Type | Price Range ($) | Cutting Width (inches) | Max Speed (inches/sec) | Features | Warranty (Years) | Cost-Effectiveness Rating |

|---|---|---|---|---|---|---|

| Entry-Level Cutter | 500 - 800 | 24 | 20 | Basic Software, Manual Feed | 1 | 3/5 |

| Mid-Range Cutter | 800 - 1500 | 30 | 30 | Advanced Software, Auto Feed | 2 | 4/5 |

| High-End Cutter | 1500 - 3000 | 54 | 45 | Professional Software, Contour Cutting | 3 | 5/5 |

| Industrial Cutter | 3000+ | 60 | 60 | Heavy Duty, High Volume Production | 5 | 5/5 |