The demand for PPF machines in the automotive industry is growing rapidly. A recent report from MarketsandMarkets predicts that the global paint protection film market will reach $2.2 billion by 2025. This rise reflects a shift toward higher demand for advanced protection solutions for vehicles. PPF machines offer reliability and efficiency, making them essential for businesses focused on vehicle customizations.

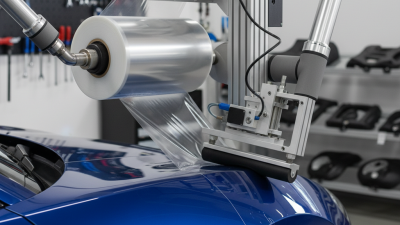

Incorporating a PPF machine can greatly enhance your service offerings. These machines provide precise application, reducing wastage and improving quality. However, not all machines provide the same level of performance. Some users report challenges with installation techniques and material compatibility. It’s crucial to choose a high-quality PPF machine that suits your specific business needs to avoid potential frustration.

Understanding these elements is vital for maximizing investment. PPF machines can generate significant revenue when used correctly. However, navigating the various options requires careful consideration and occasional reevaluation of your operational processes. Ensure that your choice supports not just current needs, but also future growth in your industry.

PPF machines are essential for businesses seeking to enhance their production capabilities. These machines apply a protective film to surfaces, ensuring durability and longevity. They are commonly used in various industries, from automotive to signage. Understanding how PPF machines work is key to leveraging their full potential.

The functionality of PPF machines lies in their precise application processes. They can cover large surfaces quickly and evenly. This efficiency can significantly reduce labor time and costs. However, operating such machines requires skill and training. Overlooking this can lead to inconsistent results.

Tip: Pay attention to the calibration of your machine. Regular checks can prevent waste and enhance quality. Additionally, train your team well to handle the equipment. Mistakes early on can lead to costly corrections later. Each job can serve as a learning opportunity, refining your approach over time.

The integration of PPF machines in business operations offers significant advantages. A recent report by MarketsandMarkets revealed that the global market for PPF machines is expected to grow by 8% annually until 2026. This growth highlights the increasing reliance on these technologies.

PPF machines enhance efficiency in various sectors. They automate processes, reducing manual labor and minimizing errors. For instance, a manufacturing plant can cut production time by up to 30% when utilizing these machines. However, not all businesses fully capitalize on this potential. Some still rely on outdated methods. This reluctance can hinder growth.

Moreover, PPF machines improve product quality and consistency. A study noted that businesses that adopted PPF technology saw at least a 20% increase in product uniformity. Yet, the initial investment can be challenging for some companies. This financial hurdle may deter smaller businesses from transitioning. Ultimately, evaluating the broader implications of adopting PPF technology is crucial for long-term success.

When selecting a PPF machine for business, several factors come into play. First, consider the size of your operation. A small shop may not need a heavy-duty model. On the other hand, larger businesses might require more advanced technology. Think about the volume of work you handle. Machines that can operate continuously are beneficial for high-demand environments.

Next, evaluate the types of materials you will be using. Some PPF machines work better with specific film types. Understand the compatibility of your chosen model with these materials. Ease of use is another critical factor. A complex interface can slow down your workflow. Simple controls help staff adapt quickly, though training may still be needed.

Maintenance is often overlooked. Regular upkeep is essential for optimal performance. A machine that is hard to service can lead to downtime. Think about the availability of support and parts. Reflecting on these elements can guide your choice wisely. The right machine can lead to increased productivity and reduced stress in your operation.

| Feature | Importance | Recommendation |

|---|---|---|

| Production Speed | High production speed increases efficiency and reduces labor costs. | Choose machines with speeds above 1,000 units/hour for optimal performance. |

| Ease of Use | User-friendly interfaces streamline operations and reduce training time. | Look for intuitive controls and comprehensive user manuals. |

| Durability | A durable machine reduces maintenance costs and downtime. | Select machines made from high-quality materials with warranty options. |

| Support and Service | Reliable support ensures quick resolution of issues and maintenance. | Prioritize suppliers known for responsive customer service. |

| Size and Footprint | The machine's size directly impacts the layout of your workspace. | Assess your available space when selecting the machine dimensions. |

PPF machines have revolutionized various industries by providing a more efficient alternative to traditional methods. According to a recent industry report, PPF technology can reduce production times by up to 30%. This significant improvement allows businesses to increase output without compromising quality. Traditional methods often require multiple labor-intensive steps. In contrast, PPF machines streamline these processes into a single operation.

Cost-effectiveness is another important factor. A survey indicated that companies using PPF machines saw a 25% decrease in operational costs over two years. However, the initial investment in PPF technology can be daunting. Many businesses hesitate to switch due to high upfront costs. They worry about ROI and fear potential disruptions during the transition. Yet, the long-term benefits often outweigh these concerns.

Moreover, the precision offered by PPF machines is unmatched. Studies reveal that PPF can achieve a production accuracy of 95%, whereas traditional methods commonly fall short. This precision minimizes waste and enhances product quality. Despite these advantages, some businesses remain skeptical. They question whether the investment aligns with their unique requirements.

The chart above illustrates the production efficiency of PPF machines compared to traditional methods, showcasing significant advantages in automation and output. While PPF machines exhibit an efficiency of 85%, traditional methods reach only 60%. This highlights the potential benefits of integrating modern technology into business operations.

When considering the investment in a Paint Protection Film (PPF) machine, cost-effectiveness becomes a significant factor. These machines often have a higher upfront cost, but their lifetime savings can be significant. Businesses can save on labor costs by automating the application process. This means fewer mistakes. With precision equipment, the quality of the output improves. Higher quality films can attract more customers.

Investing in PPF machines leads to a better return on investment (ROI). As demand for vehicle protection grows, a PPF machine can streamline operations. The initial costs may seem daunting. However, businesses can see a quicker turnaround by adopting advanced technology. Fewer product returns also contribute positively to the bottom line. In many cases, improved customer satisfaction builds a strong reputation.

Yet, it’s essential to reflect on the decision-making process. How often will a PPF machine be used? Will your target market sustain high demand? Ultimately, weighing the tangible benefits against investment risk is crucial. Some businesses may struggle to adapt to new technologies. Deciding on a PPF machine should involve careful planning and realistic assessments.