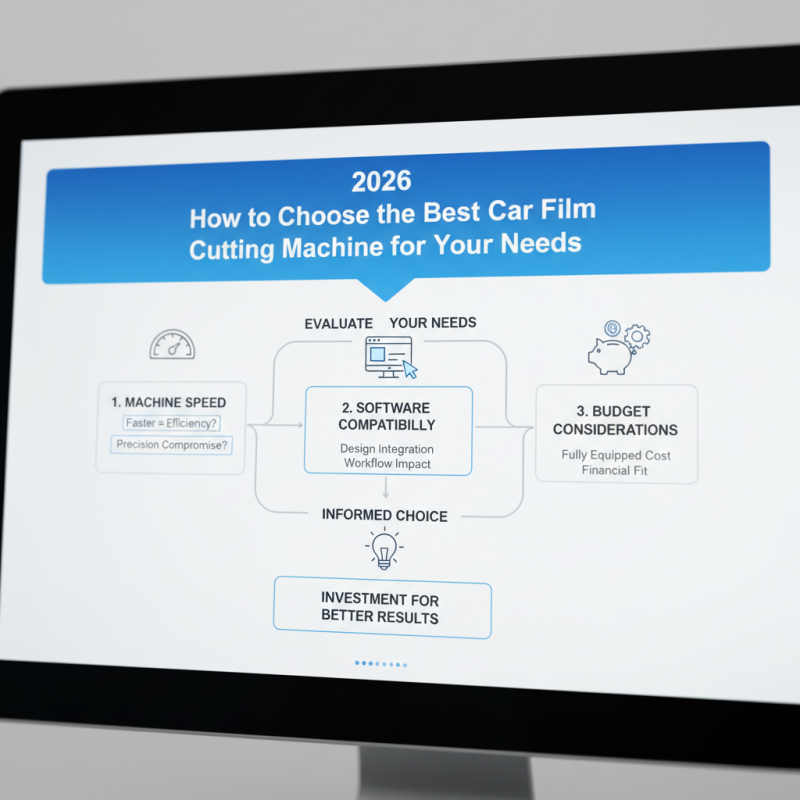

Choosing the right Car Film Cutting Machine can be challenging. With so many options available, it's crucial to evaluate your specific needs. These machines are designed to enhance efficiency and precision when applying films to vehicles.

Many factors come into play. For instance, consider the machine's speed. A faster machine may seem ideal, but does it compromise precision? Think about the software compatibility as well. Some machines work better with certain designs, impacting your workflow.

Also, budget is a significant concern. You might find a fully equipped machine, but does it fit your budget? Reflecting on these aspects will help you make a more informed choice. A Car Film Cutting Machine is an investment, and the right decision can lead to better results in your projects.

Car film cutting machines play an essential role in the automotive industry. They allow for precision and customization, which is crucial for achieving high-quality results. With these machines, every curve and detail of a vehicle can be captured accurately. This results in a perfect fit for window tinting or protective films. Without this technology, mistakes could lead to waste or unsatisfactory finishes.

Selecting the right car film cutting machine is not always straightforward. Many features need consideration, such as blade types and software compatibility. Some users find the initial learning curve steep. However, investing time in understanding machine settings can lead to better outcomes. Each machine has its quirks, which may take time to master.

Moreover, the importance of maintenance cannot be overlooked. Regular upkeep ensures optimal performance. Users should regularly check blades and update software. Neglecting these tasks can lead to errors and frustration. It's a reminder that perfection requires ongoing effort and attention. Choosing wisely and learning continually can make all the difference.

| Feature | Description | Importance |

|---|---|---|

| Cutting Precision | The ability to make accurate cuts in different materials. | High precision ensures professional quality installations. |

| Software Compatibility | Supports various design software for seamless integration. | Compatibility enhances the functionality and user experience. |

| Material Versatility | Capable of cutting different types of films (e.g., PPF, tint). | Maximizes the range of services you can offer. |

| Ease of Use | User-friendly interface and straightforward controls. | Reduces training time and increases productivity. |

| Speed | Fast cutting speeds to enhance workflow. | High speed contributes to better efficiency and output. |

| Durability | Build quality that ensures long-lasting use. | Durability reduces replacement costs over time. |

| Support and Training | Availability of customer support and training resources. | Good support ensures maximum utilization of the machine. |

When selecting a car film cutting machine, several key features deserve close attention. The cutting speed is crucial. According to a recent industry report, machines with higher speeds can improve productivity by up to 25%. A faster cutter allows you to produce more films in less time, which can greatly impact your shop’s efficiency.

Another important feature is the machine's precision. Precision impacts the quality of the cut film. Poorly cut films can lead to waste and rework. An optimal cutter should have a margin of error below 1 mm. Checking reviews and specifications can help gauge this precision. The software compatibility is also a big factor. The right software should support various file formats and have a user-friendly interface. A third of users claim they face challenges due to complicated software, slowing down their workflow.

Lastly, consider the machine's durability. Research shows that nearly 20% of buyers regret their choice because of fragile components. To avoid these issues, look for materials and construction quality. This is crucial for long-term investment. Remember, a machine's purchase is not just about the price tag; it's about future reliability.

When choosing a car film cutting machine, it's crucial to evaluate the options available. Various types cater to different needs. For instance, computer-controlled machines offer precision. They typically use software to optimize cutting patterns. This eliminates waste and improves workflow efficiency. According to industry reports, these machines can reduce film usage by up to 20%.

There are also manual cutters. They are often more affordable but require skilled operators. The accuracy may vary, leading to potential material waste. Data shows that improper cuts can result in a 15% increase in costs over time. Understanding the nuances between these options is essential. A skilled operator can mitigate risks with manual tools, but challenges remain.

Laser-cut machines are another popular choice. They are known for high precision and speed. However, they usually come with a higher price tag. Trade data indicates that around 30% of businesses using these machines experience a notable increase in customer satisfaction. Yet, the initial investment can be daunting for small shops. Balancing cost and functionality is key in this decision-making process.

When choosing a car film cutting machine, budget plays a crucial role. The initial cost is often enticing, but hidden expenses can arise. You might find yourself paying more for replacement parts or software updates. This highlights the importance of evaluating long-term value.

Consider your specific needs. A machine that fits your budget may not serve your purposes well. If you're cutting high-volume orders, investing in a reliable machine is worth it. An inexpensive option might break down frequently, leading to delays and lost revenue. Think carefully about how often you'll use the equipment and what features you truly need.

Additionally, research is essential. Look for reviews that highlight both positive and negative experiences. Understanding common issues can help you avoid pitfalls. Are there any recurring complaints? Pay attention to these details, as they can influence your decision. Sometimes, spending slightly more means better support and reliability down the line.

When it comes to maintaining a car film cutting machine, regular upkeep is crucial. Ensuring the blades are sharp is essential for precision. Dull blades can lead to uneven cuts. This oversight can waste materials and time. Check the blades frequently for any signs of wear.

Additionally, keeping the machine clean will preserve its functionality. Over time, dust and debris can accumulate, affecting performance. A quick wipe down after use can make a significant difference. Use a soft cloth; avoid harsh chemicals that could damage sensitive components.

User experience can be improved by establishing a routine. Schedule maintenance checks to avoid last-minute repairs. Be mindful of unusual noises or vibrations during operation. These could indicate underlying issues. If something feels off, addressing it sooner is always better than waiting.