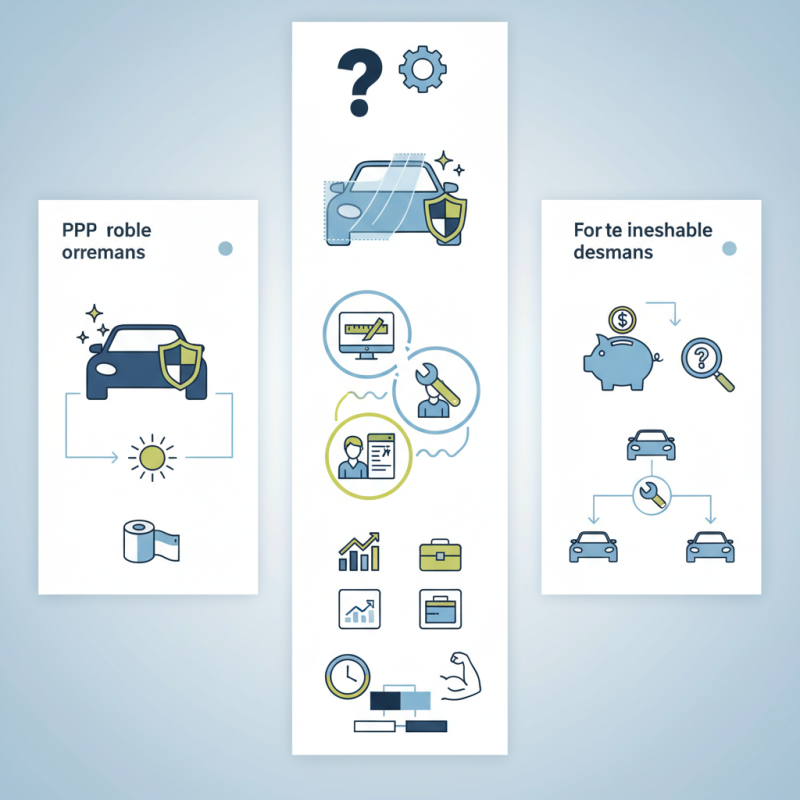

When it comes to safeguarding your vehicle, a PPF cutting machine plays a crucial role. Paint Protection Film (PPF) shields your car from scratches, road debris, and UV damage. Choosing the right machine can significantly enhance your installation process and outcomes.

The market offers various PPF cutting machines, each with unique features. Some have advanced software for precision cuts, while others prioritize user-friendliness. For beginners, ease of use is vital. For experienced users, custom features can maximize efficiency. It's essential to weigh these options carefully.

However, purchasing the best machine can be overwhelming. Budget constraints may limit choices, leading to compromises on features. Not every machine suits every application. Reflecting on your specific needs is fundamental. Ultimately, investing in a quality PPF cutting machine is about durability and performance.

Paint Protection Film (PPF) is crucial for vehicle longevity. It protects the paint from scratches, chips, and stains. This thin, clear layer absorbs impacts that could damage the surface. According to industry data, around 70% of new car buyers are considering PPF to maintain their vehicle's aesthetic. Investing in PPF can significantly increase a vehicle's resale value.

The application of PPF requires precision and skill. Poor technique could result in air bubbles or misalignment. A report highlights that approximately 20% of installations show issues on first inspection. Such flaws can lead to peeling or discoloration over time. This suggests that not all installations are done to the same standard, making it essential to choose experienced individuals.

A well-applied PPF not only provides protection but also enhances the car's appearance. It maintains that glossy finish that many drivers love. However, a lack of maintenance can result in yellowing or damage. Many car owners often overlook the need for regular care, which is vital for longevity. Understanding these aspects can ensure better decisions when considering PPF for your vehicle.

This chart represents the estimated sales volume of different types of Paint Protection Film (PPF) cutting machines over the past year, showcasing their popularity and demand in the automotive market.

When selecting a Paint Protection Film (PPF) cutting machine, several key features are vital. One significant aspect is the software compatibility. Advanced software allows for precise cuts, minimizing material waste. According to a recent industry report, machines with user-friendly interfaces increase productivity by up to 30%. Users often underutilize this feature, which leads to inefficiencies.

Another important factor is the cutting speed. High-speed machines can process large volumes quickly, which is essential in busy automotive shops. Some machines offer adjustable speed settings, allowing customization based on the complexity of the cutting design. Data shows that shops with high-speed cutters have reported a 25% decrease in turnaround times. However, a common oversight is not calibrating the speed correctly for different materials, which can damage films.

Durability is also worth considering. The longevity of a PPF cutting machine influences long-term costs and efficiency. Moreover, some cutters come with warranties, indicating their reliability. Yet, users tend to overlook maintenance routines. Neglecting regular care can lead to performance degradation. This area often requires reflection, as routine checks can save significant costs in the long run.

When considering the best PPF cutting machines, evaluating top brands is essential. These brands offer various features tailored to specific vehicle needs, such as thickness and material type. Many models come equipped with user-friendly software, allowing for easy design adjustments. The cutting precision varies, which is crucial for achieving clean edges. Some machines shine in cutting intricate patterns, while others excel in speed.

However, it's important to note that not all features may be useful for every user. Some machines are complex, requiring a learning curve. Others may be over-engineered for basic needs. It’s common for beginners to feel overwhelmed by numerous options. Many operators realize that investing in additional tools enhances their machine's performance. A well-rounded setup often leads to better results.

Moreover, support and community feedback play a role in brand comparison. Some brands provide excellent customer service, while others lag behind. Reading user reviews can reveal hidden drawbacks. You may find that some machines have quirks that need attention. There’s always room for improvement, and recognizing this can guide future purchases.

When considering a PPF cutting machine for your vehicle, budget plays a critical role. It's essential to define what you can afford before diving into options. Think about how much you want to invest. Some machines may seem appealing but tend to drain your wallet. Others are budget-friendly yet still offer excellent performance.

Decide on the features that matter most to you. Do you need high precision, or is a basic machine sufficient? Remember, a higher price doesn't always equal better quality. Some users have experienced issues with more expensive models, leading to waste and frustration. Balancing quality and price can be challenging. You may find the perfect middle ground after some trial and error.

Another consideration is long-term costs. Factor in material expenses and maintenance. A mediocre machine may save you money upfront but cost more over time. Look for reviews that highlight customer experiences. Real-world feedback can guide you in making a more informed decision. Finding the right machine is a journey, and sometimes, learning from mistakes enhances your understanding.

Maintaining a PPF cutter is crucial for its longevity and efficiency. According to industry reports, poorly maintained machines can experience a 30% reduction in performance. Regular cleaning is essential; debris buildup can cause inaccurate cuts.

Wipe down the blades and the cutting surface after every use. This simple step ensures precise results and reduces wear over time.

Calibrating the machine regularly is another vital maintenance task. A study showed that 40% of users neglect this, leading to uneven cuts. Make it a habit to check the settings before each job. This ensures that the machine operates at its best. Moreover, using high-quality materials can influence not just the output but also the lifespan of your cutter.

Even with diligent care, issues can arise. Blades may dull or misalign, affecting performance. It’s recommended to inspect the blades frequently and replace them at signs of wear. A proactive approach to maintenance leads to smoother operations and better results. With these tips, users can achieve an optimal balance of performance and durability.