When it comes to automotive customization, a Car Film Cutting Machine is essential. This device allows professionals to create precise cuts in vinyl films. These films are often used for window tinting and vehicle wraps. Choosing the best one can be challenging, and mistakes can be costly.

There are many models on the market today. Some offer advanced features, while others are basic yet effective. Professionals need to consider their specific requirements. Factors like cutting speed and accuracy could determine success. It's easy to overlook the importance of these details, leading to subpar results.

Additionally, training and experience play a significant role. Even the best Car Film Cutting Machine requires skilled hands. It’s crucial to recognize limitations and seek improvement. Continuous learning is necessary for mastering this craft. Every cut counts, and precision is vital in achieving the desired outcome.

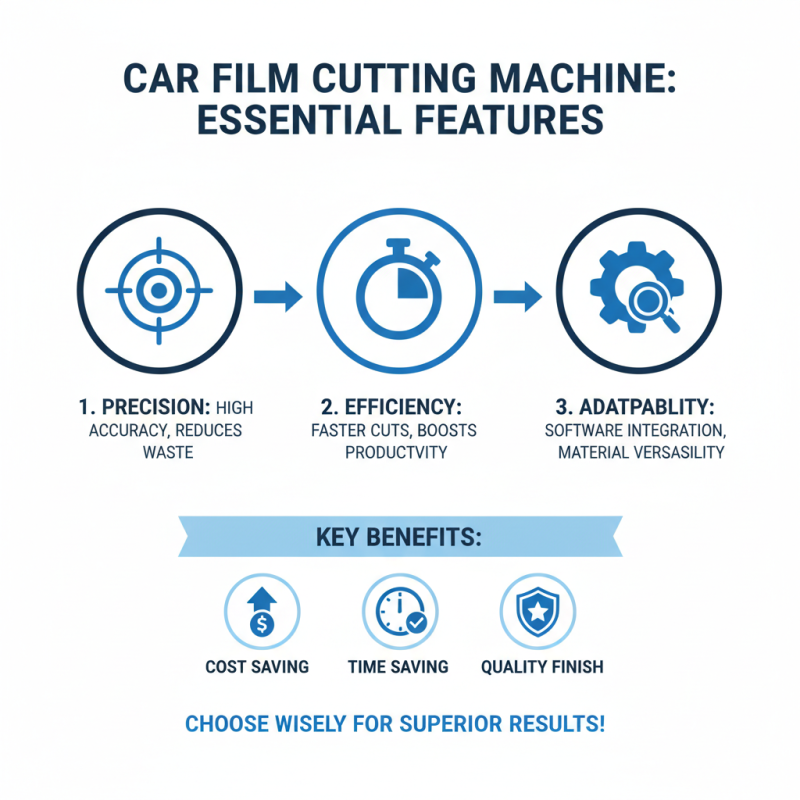

When selecting a professional car film cutting machine, certain criteria must be prioritized. One key aspect is precision. According to industry reports, machines that maintain a cutting accuracy of ±0.1 mm significantly reduce film waste. This precision advances both efficiency and cost-effectiveness. Operators should look for features that enhance this accuracy, such as advanced blade technology and software integration.

Speed is another critical factor. Data shows that machines capable of cutting films at speeds above 2 meters per minute allow professionals to handle larger projects in shorter time frames. However, high speed must not compromise quality. Many machines sacrifice precision for speed, leading to subpar results. Addressing this balance is vital for any professional.

User-friendliness must also be considered. A complicated machine can slow down workflow. Training for new users can be extensive, hindering productivity. It’s essential that manufacturers prioritize intuitive designs. A recent study found that machines with user-friendly interfaces saw a 30% increase in operator efficiency. Evaluating these aspects ensures that professionals can perform high-quality work without unnecessary delays.

When considering a cutting machine for car film, you need to focus on essential features. Precision is key. Look for a machine that offers high accuracy in cutting. This can drastically reduce material waste. Efficiency matters too. A faster machine will help you complete projects quickly, especially in a busy environment.

Another important aspect is user-friendliness. The software should be easy to navigate. Complicated features can lead to mistakes. A touchscreen interface can streamline the process. Don't overlook the importance of compatibility. The cutting machine should work well with various materials. Check if it supports different film types.

Tips: Always read reviews before making a purchase. Learn from past users’ experiences. This can guide you in choosing wisely. Test the machine if possible. Figure out if it meets your specific needs. Finally, consider the warranty and support options. These can save you from future headaches.

When choosing a car film cutting machine, various brands offer a range of options. A recent industry report highlights that 75% of professionals prefer machines with advanced features. These features include precise cutting technology and user-friendly software. Models that integrate automation are gaining popularity. Users appreciate the time-saving benefits.

Some brands have received mixed reviews regarding their durability. While some machines are built to last, others may require frequent maintenance. A survey indicated that 40% of users encountered issues after a few months of use. Buyers should consider this when making a decision. Quality is as crucial as technology.

Moreover, price points vary significantly across brands. Cost rarely reflects performance. A budget machine can sometimes outperform a high-end model. Users frequently report satisfaction with lower-cost options that meet professional standards. The best choice may not always be the most expensive one. It's essential to weigh features, reliability, and overall value.

The benefits of using a car film cutting machine for professionals are substantial. These machines enhance precision. Research indicates that accurate cutting reduces film waste by approximately 30%. Reducing waste saves costs for professionals and clients alike. Efficiency is another major advantage. Cutting machines can process large projects swiftly. This ability allows professionals to take on more work without compromising quality.

These machines are also user-friendly. Many have intuitive interfaces, which reduce training time. However, reliance on machines can lead to complacency. Professionals may skip essential manual skills. It's vital to balance machine use with traditional cutting techniques to maintain versatility. Some studies show that skilled labor is still invaluable. A combination of tech and skill often yields the best results.

Moreover, adaptability is crucial in the ever-evolving automotive industry. Cutting machines can handle various films, from window tint to protective wraps. They allow for customization, meeting specific customer needs. However, inadequate maintenance can lead to errors. Regular checks are necessary to ensure machines function correctly. Investing in a quality cutting machine is wise, but professionals must remain vigilant. Balancing technology and skills is essential for ongoing success.

| Feature | Description | Benefit | User Rating |

|---|---|---|---|

| Precision Cutting | High-accuracy blade for intricate designs. | Ensures a perfect fit for car windows and other surfaces. | 4.8/5 |

| Speed | Fast cutting speeds for increased productivity. | Reduces installation time significantly. | 4.5/5 |

| Software Compatibility | Works with various design software. | Flexibility in design choices for professionals. | 4.7/5 |

| Ease of Use | User-friendly interface for quick mastery. | Less training time for staff. | 4.6/5 |

| Portability | Compact design for easy transportation. | Ideal for mobile service professionals. | 4.4/5 |

Maintaining a car film cutting machine is crucial for achieving precise cuts and extended lifespan. Regular cleaning of the cutting blades helps prevent residue buildup, which can affect accuracy. Use a soft cloth for routine wipe-downs. Pay attention to any signs of wear on the blades. If they seem dull, it's time for a replacement. Ignoring this can lead to uneven cuts and wasted materials.

Another important aspect of maintenance is the calibration of the machine. An uncalibrated machine may produce incorrect measurements. Check the settings regularly and adjust as needed. Keeping a log of calibration sessions helps track when adjustments are necessary. This can save time and frustration later.

Lastly, don’t overlook the importance of software updates. Machines often rely on software to operate effectively. Outdated software can lead to glitches and decreased efficiency. Ensure that the machine is connected to the internet for automatic updates. By fine-tuning maintenance practices, users can optimize the performance of their car film cutting machines.